Conductive wool replaces wiring and circuits in WoolTech electronics

Wool takes the place of wiring, plastic and circuit boards in electronic devices created by designer Hinna Khan, a recent Central Saint Martins graduate inspired to find a new use for the material after watching farming documentaries.

Still in early development, Khan's WoolTech is made from a novel wool-based biomaterial, in which conductive pathways can be created using lasers.

This carbonises the material so it carries electricity, while the un-carbonised sections provide natural insulation.

The innovation could help to tackle the issue of e-waste, reimagining components that are usually made from a mix of metals and petrochemicals using a single organic, biodegradable material.

It could also help to lower demand for mined metals, which are associated with dangerous working conditions and child exploitation. However, Khan originally came to the idea after exploring solutions to a different problem: wool waste.

From watching farming documentaries – especially Clarkson's Farm, following former Top Gear host Jeremy Clarkson – she learnt that farmers in the UK have been shearing sheep purely for animal welfare reasons, with the wool itself having little value.

"The British wool industry is collapsing," said Khan. "Coarse-grade fleeces now fetch as little as 60 pence per kilogram and are often discarded or burnt, costing more to shear than returns received."

"As a result, rare British sheep breeds are being crossbred or lost in pursuit of 'higher value' wool, threatening biodiversity, heritage and local farming livelihoods."

This drove her to find new income streams for wool, with the hope to "reimagine the entire wool industry infrastructure".

"When I looked more closely at the fibre itself, I was amazed," Khan told Dezeen. "It has incredibly high-performance technical properties that are severely underutilised and largely unknown. Yet public perception still reduces wool to something simply 'fluffy' or 'heritage'."

The emerging designer, who started WoolTech in her final year at London design school Central Saint Martins, brainstormed applications based on wool's technical properties, such as fire resistance and moisture-wicking.

"That's when I landed on electronics," said Khan. "Wool unexpectedly ticked all the boxes, meeting technical standards and British regulations. The electronics industry is also so huge that I knew any innovation in this area with wool would really boost its value and demand."

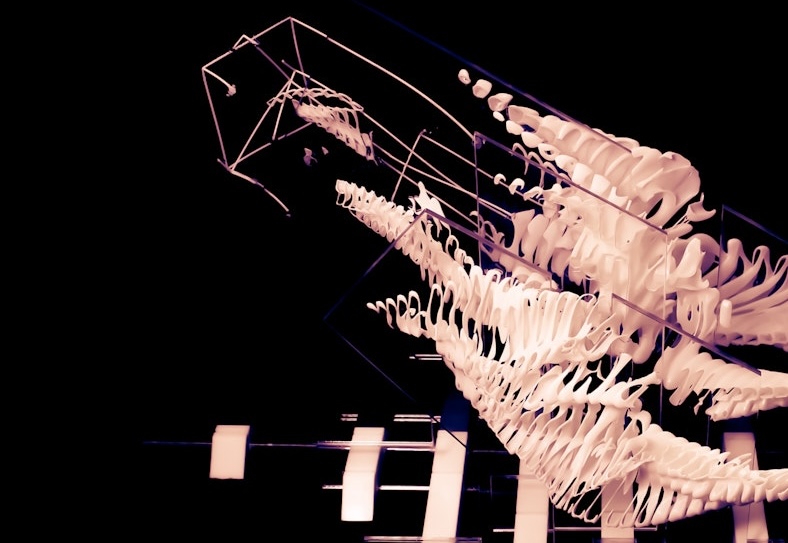

Khan's prototypes, including a torch and a circuit board, are at this point proofs of concept based on extensive research. To develop working prototypes, she is planning to collaborate with or license the laser technology of PulpaTronics, a London-based start-up making electronics from paper.

She said she had originally experimented with using conductive inks made from carbonised wool, inspired by Bare Conductive, but had given up on this approach when she realised it required too much energy.

PulpaTronics laser-based carbonisation process, however, "aligned perfectly" with WoolTech, showcasing the "material intelligence" of wool with its naturally high carbon content.

When turning wool into a usable biomaterial, Khan focused on achieving the structural strength and water resistance necessary for electronics and experimented with over 80 different recipes, turning her kitchen into a lab.

She used Swaledale wool – one of the coarsest, least valued breeds, mainly used for carpets – and ultimately chose a binder derived from agricultural protein waste. There are no other additives.

Khan's prototypes are completed with a water-soluble solder that she says makes for easy end-of-life disassembly, and the biomaterial printed circuit board (PCB) can be sanded and re-lasered for reuse.

The material can be moulded into any form, biodegrades in three to four months, and the approach is twice as cost-effective as metal electronics, according to the designer.

"Coming from a non-tech background, I questioned the traditional throwaway design of electronics and PCBs – resin-coated, glued, impossible to disassemble and overly complex," said Khan. "While technology often drives sustainability efforts, it rarely addresses its own environmental impact. Sustainable hardware alternatives are nearly non-existent."

"WoolTech also champions social sustainability and justice by generating new income for hill farmers, revaluing UK heritage breeds and preserving biodiversity," she continued.

"This project aims to pave the way for a regenerative materials future by inspiring industries to adapt heritage materials for today's needs."

Khan is not the only designer innovating with wool. Clothing brand Sheep Inc is using it to make all-natural swim shorts, while Formafantasma combined it with latex to create an alternative to plastic upholstery foam.

The post Conductive wool replaces wiring and circuits in WoolTech electronics appeared first on Dezeen.