Blast Studio launches Cupsan biomaterial made from London coffee cups

London's discarded takeaway coffee cups are given a long and useful life in Cupsan, a new biomaterial that local design practice Blast Studio has started producing at scale.

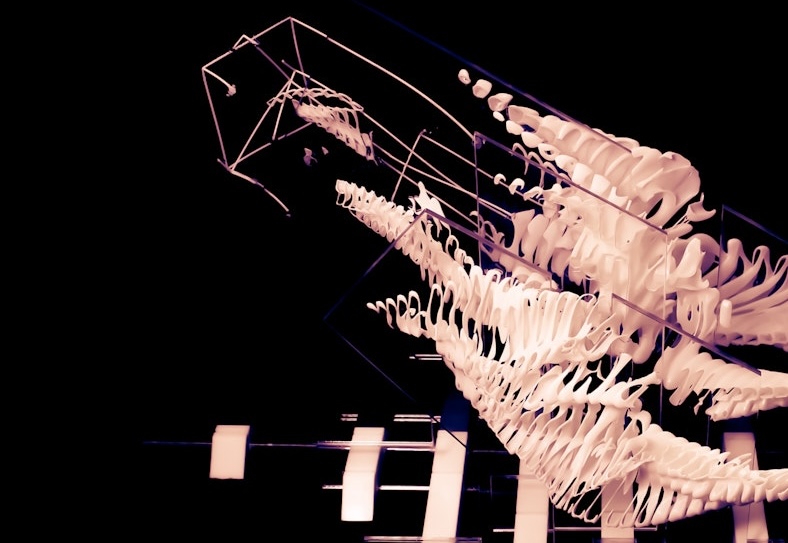

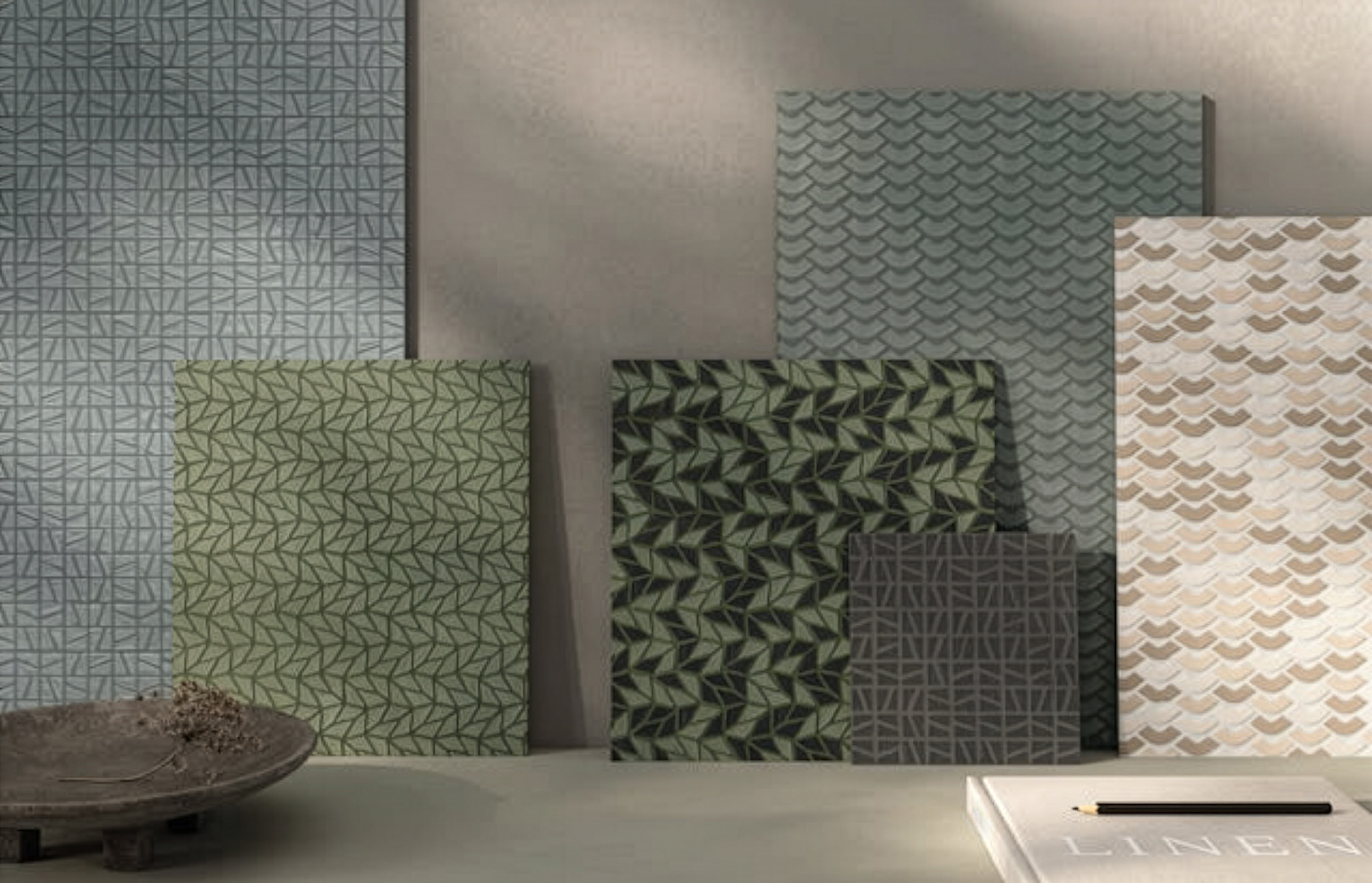

A warm and flecked material marrying the textural qualities of stone and earth, Cupsan comes in high-density boards that can be used similarly to MDF. It can also be moulded into shapes to make objects such as pendant lights.

Blast Studio has been quietly presenting versions of Cupsan for years, as the material initially served as the substrate for the designers' pioneering work with mycelium.

Mycelium can be grown on many carbon-rich waste materials such as straw and sawdust, but Blast Studio began using single-use coffee cups as its solution soon after relocating from Paris to London in 2019.

"In London, we were struck by the sheer number of people walking around with takeaway coffee cups," Blast Studio co-founder Paola Garnousset told Dezeen. "We also knew how problematic these cups are for recycling – they're lined with plastic and contaminated with food, so most of them end up in landfill."

However, the designers eventually began focusing less on mycelium and more on their paper-pulp substrate after realising the mycelium had its limitations, while their substrate was strong enough on its own.

"Mycelium requires sterilisation, very controlled growth conditions, and it's slow to scale," said Garnousset. "Not using mycelium meant we could reduce energy demand, scale production more easily, and create a more functional material for interiors."

The team's path to commercialising Cupsan was set when their supplier, waste-management company First Mile, delivered a full tonne of the single-use coffee cup to their door.

In that moment, the designers were hit by the scale of the problem, realising that it represented only one out of the 30,000 tonnes of coffee cup waste the UK produces every year – and that very little was being done with it.

"We understood that if we wanted to have a real impact, we had to step out of the lab and confront the realities of the construction and waste industries," said Garnousset.

The studio is manufacturing Cupsan independently and is selling it primarily as a board, with each square metre containing around 840 coffee cups.

Blast Studio says the finished material can be cut, drilled, nailed, varnished and glued just like wood, and that it is similarly "forgiving", as it can be sanded and repaired in different ways to give it new life.

To make the material, Blast Studio shreds and sterilises the cups to create a paper pulp, removing their plastic lining during the process. The designers add a plastic-free binder to hold the fibres together and leave it to cure, during which time the material's agglomerated texture forms naturally.

They sometimes add pigments – mainly natural ones such as ochres, charcoal and chalk – and have also experimented with waste streams such as brick dust to colour the material.

It is also possible to harness the existing colour in the packaging waste, as the studio once did with the red coffee cups from UK chains Gail's and Costa Coffee, yielding a pale pink board.

The studio has also begun testing ways to make small design pieces out of the plastic lining, which is removed during the production process and constitutes around five per cent of each coffee cup.

Blast Studio also undertakes custom projects involving Cupsan, where it uses the client's own waste streams. For instance, the designers worked with TMTO Architecture on the Happy Sky Bakery in central London, which features lampshades and panels made using waste coffee cups from the store's other location.

Garnousset says that from its early days working with coffee cups, Blast Studio has loved the idea of taking something ordinary and short-lived and transforming it into something that lasts.

"In a way, it's like bringing the coffee cup back into the form of a tree," said Garnousset. "For us, the cup has become a symbol of the megacity, of speed and disposability."

"By reworking it into Cupsan, we try to slow it down, transforming it into a material that could last for decades."

Blast Studio's previous work has included the Tree Column, which was 3D printed with living mycelium and could be harvested for mushrooms before becoming a structural building element.

The post Blast Studio launches Cupsan biomaterial made from London coffee cups appeared first on Dezeen.