Hawaii company converts surfboard waste into construction blocks

Surf Block Maui has developed a system that converts foam from surfboard-shaping into building materials for local construction to ameliorate multiple problems in Hawaii.

Surf Block Maui was founded on the Hawaiian island to address waste left behind by the surfboard industry, which uses EPS (known as styrofoam) in the production process.

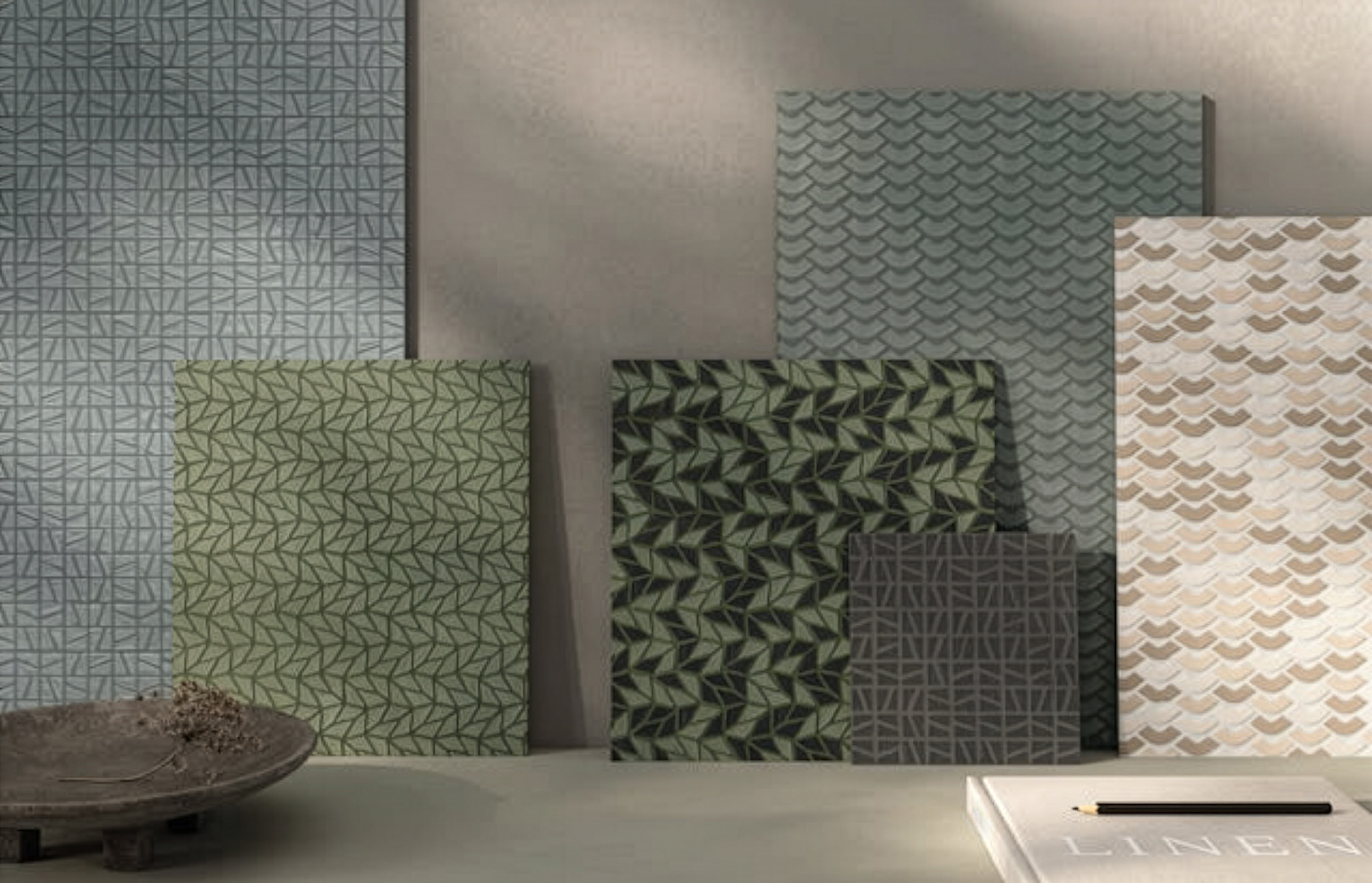

The company has created a process that takes the EPS and converts it into composite material for insulated composite concrete form (ICCF) blocks – an alternative to concrete masonry units (CMUs).

When reinforced with steel, the blocks can be used to make up structural walls. These walls are then coated with poured-in-place concrete and a moisture barrier.

Surf Block founder Scott Sellers said the company aims to solve a host of problems experienced by the island, the first being a need to cut down the amount of waste from surfboard production.

Other benefits include reducing the amount of concrete used in construction, most of which needs to be imported into the island, a costly expense for locals, not to mention the carbon cost of transporting materials.

Surf Block says that its initiative cuts down the need for concrete by as much as 30 per cent on the island.

"We're on an island with limited space, limited resources, and landfills that are filling up fast," said Sellers.

"Creating building materials from local waste is environmentally responsible and essential. It allows us to reduce imports, cut emissions, and build in a way that's truly place-based."

Sellers is also the principal architect of Hawaii Off Grid Architecture and Engineering (HIOG), and has begun implementing the blocks into local homes.

This initiative is especially important after the devastation caused by the 2023 wildfires on the island.

Surf Block claims that the homes created with the materials also have downstream benefits, such as increased insulation and durability in case of future disasters, including earthquakes, fires and hurricanes.

Sellers and his team are also managing the collection and production of the blocks, allowing his companies to oversee the whole process.

For Sellers, the initiative resonates with the culture of Hawaii, given surfing's importance to the islands.

"Surfing was born in Hawaii, and shaping boards is still a part of daily life here," said Sellers.

"Being able to take that leftover foam and turn it into something strong, lasting, and community-serving carries real meaning for us."

Surf Block contends that even diverting five to 10 per cent of EPS waste could contribute to the construction of 100 homes on the island.

Some of the homes already built are being supplemented by wood-frame upper storeys, resting on the Surf Block bases. Currently, two homes have been built on the island, with three more in permitting as rebuilds for the 2023 fire.

Other projects that feature recycled plastic include a community centre in Jakarta built with 11 tonnes of plastic waste and a Hawaii resort with a thatched roof made with recycled plastic.

The photography is courtesy of Surf Block Maui.

The post Hawaii company converts surfboard waste into construction blocks appeared first on Dezeen.