Controlled Variation: Mirage Makes the Case for Industrial Craftsmanship

The winners of the A+Product Awards have been announced! Looking ahead to next season? Stay up to date by subscribing to Architizer's A+Product Awards Newsletter.

Ceramics have always carried a double life. On one hand, they are industrial, born from kilns, presses and chemistry. On the other hand, they are cultural artifacts, tied to centuries of craft and to the ways surfaces shape our experience of space. For architects and designers, porcelain stoneware is rarely a neutral background. It must deliver performance in terms of durability and maintenance, but also atmosphere: how light plays across it, how it feels underfoot, how it communicates a project’s values.

Mirage, based in the heart of Italy’s ceramic district in Modena, has spent the last fifty years working at this intersection. Founded in 1973, the company has become one of the most recognizable names in architectural surfaces, with products specified in more than 160 countries. Its in-house laboratory, Atelier Mirage, operates as a think tank: an incubator for collaborations with architects, interior designers and artists. Here, new collections are stress-tested not only for performance but for cultural and sensory presence. That blend of science and narrative has positioned Mirage at the forefront of an industry grappling with two urgent pressures: the demand for demonstrable sustainability, and the expectation that materials contribute actively to spatial experience rather than merely “cover” walls and floors.

That backdrop made Mirage’s triple success at the 2025 Architizer A+Product Awards especially resonant. The company secured a Popular Choice Award in Sustainable Design for its ReConcrete collection — part of the wider ReSource program — and both Jury and Popular Choice Awards in Hard Surfacing, Tiles & Stone for Nagomi, which was developed in collaboration with German-Iranian architect Hadi Teherani, known internationally for projects like the sculptural Crane Houses in Cologne and Hamburg’s award-winning Dockland office building.

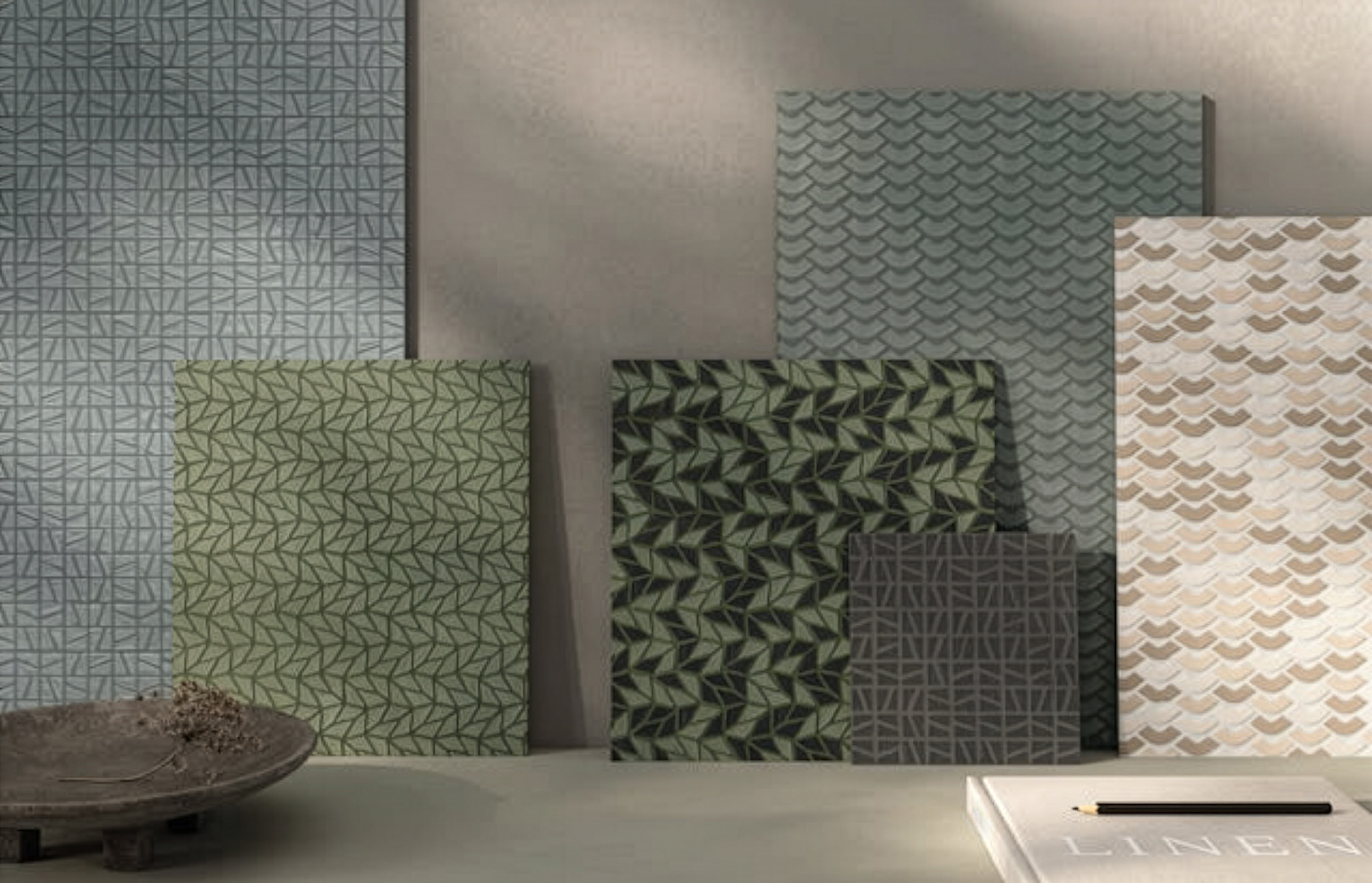

On the surface, the two collections could not be more different. ReConcrete is a rigorous exercise in circularity, embedding three distinct waste streams — raw ceramic offcuts, post-firing rejects and cathode ray glass — into porcelain slabs whose subtle tonal shifts and irregular grain echo the hand-troweled qualities of in-situ concrete. Nagomi, meanwhile, is a meditation on tactility and cultural nuance, its five tile shapes formed with recycled CRT glass powder and arranged as pixel-like mosaics that capture raking light. Their micro-textures evoke the Japanese idea of controlled imperfection, a design language that finds warmth not in ornament but in slight irregularity.

Together, these collections argue for a single philosophy: that ceramics today must be sustainable, performative and emotionally resonant.

Architizer spoke with Mirage’s Sara Bertolotti about the challenges of circular design, the role of imperfection in contemporary surfaces, and why “industrial craftsmanship” may be one of architecture’s greatest allies.

Samantha Frew: Mirage received three awards this year, one for ReSource and two for Nagomi. How do these two collections reflect different aspects of the same design vision?

Samantha Frew: Mirage received three awards this year, one for ReSource and two for Nagomi. How do these two collections reflect different aspects of the same design vision?

Sara Bertolotti: Both collections address sustainability, but from different angles. ReSource is our technical challenge: we manage three different waste streams that behave differently during firing. Raw ceramic scraps shrink, post-fired pieces are dimensionally stable and photovoltaic glass has completely different thermal expansion coefficients. Managing these variables while maintaining consistent performance is complex engineering.

Nagomi uses the same recycled cathode ray glass but focuses on surface behavior: how light captures micro-textures, how tactile qualities affect spatial perception. It’s the same commitment to sustainability, but one collection prioritizes technical performance while the other explores sensory experience.

ReSource presents sustainability as a core design principle rather than a secondary feature. How did that mindset influence the development process?

Starting with sustainability meant accepting constraints that conventional ceramic production doesn’t have. We had to develop new firing curves because ceramic scraps from different companies behave unpredictably: some contain grog, others are pure clay bodies.

The visual result — those subtle color variations and surface irregularities — comes directly from this technical complexity, not from aesthetic choices made in isolation. We also developed an alternative material sourcing network, creating a supply system that requires coordination between production phases and timing.

The material formulation uses three different waste streams. What challenges did this introduce, and how did you turn those into opportunities?

The material formulation uses three different waste streams. What challenges did this introduce, and how did you turn those into opportunities?

We developed a classification system for incoming waste: particle size, composition analysis, thermal testing. What started as quality control became a creative tool. Different waste combinations produce distinctive surface characteristics that we can now predict and specify. The “imperfections” became a controlled variable rather than a problem to solve.

You’ve exceeded 60 percent recycled content in ReSource. What would it take to go further, and where are the real limits of circularity in architectural ceramics?

Exceeding 63% requires further technical and logistical innovations. Photovoltaic glass has a specific composition that requires attention to safety regulations for building use. And sourcing quality ceramic waste consistently is difficult: you depend on other companies’ production schedules and reject rates.

The real bottleneck is logistics. Collecting, classifying and processing these materials currently costs more than virgin materials. We’re working to optimize sorting infrastructure and make higher percentages economically viable. At the moment, 60–65% seems to be the optimal balance, but we continue working to overcome these limits.

The ReConcrete surface references the irregularities of hand-applied concrete. Was the intention purely aesthetic, or does it speak to deeper questions around authenticity?

The ReConcrete surface references the irregularities of hand-applied concrete. Was the intention purely aesthetic, or does it speak to deeper questions around authenticity?

ReConcrete started with a technical observation: hand-troweled concrete has specific surface characteristics that affect both light reflection and tactility. We studied this surface visually and tactilely, then translated that artisanal gesture into a reproducible industrial process.

ReConcrete is a surface that reproduces the appearance of manually applied concrete. It’s a design choice that favors naturalness and material authenticity while maintaining all the technical performance of porcelain stoneware.

Architects today expect surfaces to do more than just look good. How is Mirage responding to demands for materials that perform in more tactile, sensory or even acoustic ways?

We’re exploring how our textures can respond to these needs. More articulated surfaces offer greater tactile richness and interact differently with light compared to smooth surfaces. It’s a research field we’re investing in to offer designers tools that go beyond pure aesthetics.

Nagomi treats surface as a form of architectural language. What kind of conversations did you have with Hadi Teherani about emotional resonance, spatial storytelling and the role of materials in culture?

Nagomi treats surface as a form of architectural language. What kind of conversations did you have with Hadi Teherani about emotional resonance, spatial storytelling and the role of materials in culture?

With Teherani, we focused on a practical problem: creating surfaces that work in minimal spaces without appearing cold or sterile. We experimented with micro-roughness levels: enough to catch raking light and provide subtle tactile feedback, but not so much that cleaning becomes difficult.

The cultural aspect came from Teherani’s observation that Japanese architecture achieves warmth through controlled imperfection rather than decoration. We translated this into specific surface parameters: controlled variation in planarity, subtle color shifts within tight tolerances, textures that reveal themselves gradually rather than demanding immediate attention.

Using cathode ray glass is a specific and symbolic gesture. Why was that material chosen, and how does it fit into the wider narrative of the Nagomi collection?

Cathode ray glass was available in large quantities as old CRT monitors were being decommissioned. From a practical standpoint, it has good thermal properties and creates interesting surface effects when incorporated into ceramic bodies.

The symbolic aspect is genuine but secondary. These screens once mediated our relationship with information and entertainment—now they’re contributing to physical architectural space. There’s something appropriate about that transformation, but we chose the material primarily because it performs well and we could source it consistently.

The collection avoids decoration for its own sake. Instead, it embraces texture and simplicity. Was this an attempt to challenge conventional definitions of luxury in ceramics?

The collection avoids decoration for its own sake. Instead, it embraces texture and simplicity. Was this an attempt to challenge conventional definitions of luxury in ceramics?

It was more about efficiency than philosophy. Complex decorative patterns require additional manufacturing steps, more quality control and often compromise durability. We found that sophisticated texture work and material quality could create more compelling surfaces with fewer production variables.

The redefinition of “luxury” emerged during dialogue with Hadi Teherani. His vision favors surfaces rich in tactile and visual qualities without being ostentatious. It turns out that restraint can be more luxurious than elaboration — but only if the fundamental material quality is exceptional.

Nagomi balances visual variation with industrial precision. What manufacturing processes did you develop to make that possible, and how scalable are they?

We developed controlled randomization in our production process. Each tile has subtle variations in surface depth and texture placement, but within established parameters. Our approach balances industrial control with the uniqueness of each piece. The goal is to maintain the artisanal soul of the product even in large production volumes.

Mirage often describes its approach as “industrial craftsmanship.” What does that actually mean inside your production facilities?

Mirage often describes its approach as “industrial craftsmanship.” What does that actually mean inside your production facilities?

Industrial craftsmanship means we apply artisanal attention to detail within industrial-scale processes. Practically, this means more quality checkpoints, tighter tolerances and production workers who understand both the technical and aesthetic goals of each product.

For example, our kiln operators don’t just follow firing curves: they understand how different atmospheric conditions affect surface development and can make real-time adjustments. We invest more in training and process understanding compared to typical ceramic manufacturing.

ReSource was designed for both residential and contract environments. Where is it actually being specified, and have any applications surprised you?

ReSource finds applications in both residential projects and the contract sector, from hotels to commercial spaces. We’re particularly struck by projects where architects choose the material specifically to communicate values of circularity and environmental responsibility through architecture itself.

When architects specify Mirage products, what tends to influence their decision most — performance, sustainability credentials, aesthetics or the conceptual narrative?

Designers seek a balance between beauty, functionality and environmental responsibility. Sustainability has become a fundamental requirement, no longer optional. What strikes us is how increasingly often the choice of material becomes part of the design narrative: it’s not just about specifying a surface, but choosing a material that contributes to the message the architecture wants to convey.

How has recognition from the A+Product Awards influenced conversations with clients and specifiers?

How has recognition from the A+Product Awards influenced conversations with clients and specifiers?

The recognition represents important validation of the path we’re following. It helps us better communicate the seriousness of our approach to sustainability and the innovation behind these products. It’s gratifying to see that research and development work is recognized by the international design community.

Atelier Mirage seems to function as an incubator for experimentation. What role will it play in shaping Mirage’s future direction?

Atelier Mirage is our think tank where we explore alternatives to more traditional ceramics in concept and approach. It’s a space for continuous research where we develop innovative and alternative visions that can then influence the evolution of our entire production.

All Atelier projects are born from collaboration with architects, interior designers and artists. We need someone who constantly stimulates and provokes us to seek new paths, new creative and material solutions. The insights that emerge from these collaborations often become the seed for our future collections. It’s essential to remain at the forefront of ceramic design innovation.

What unites ReConcrete and Nagomi is a refusal to disguise the complexity of their making. Waste streams are not smoothed away but organised into a system, textures are not homogenized but allowed to shift within tight tolerances. This is where Mirage’s notion of industrial craftsmanship becomes tangible: the recognition that the life of a material lies not in its uniformity, but in the way variation is managed and made legible.

For architects, the lesson is less about choosing a tile and more about recognizing a stance. In an era of standardization, Mirage suggests that precision and irregularity can coexist — and that the most compelling surfaces may be those that reveal, rather than conceal, the intelligence of their production.

The winners of the A+Product Awards have been announced! Looking ahead to next season? Stay up to date by subscribing to Architizer's A+Product Awards Newsletter.

The post Controlled Variation: Mirage Makes the Case for Industrial Craftsmanship appeared first on Journal.