Carbon Cell makes plastic-free alternative to polystyrene

British company Carbon Cell has used agricultural waste to make a carbon-negative and compostable alternative to polystyrene packaging and building insulation that avoids contributing to plastic pollution.

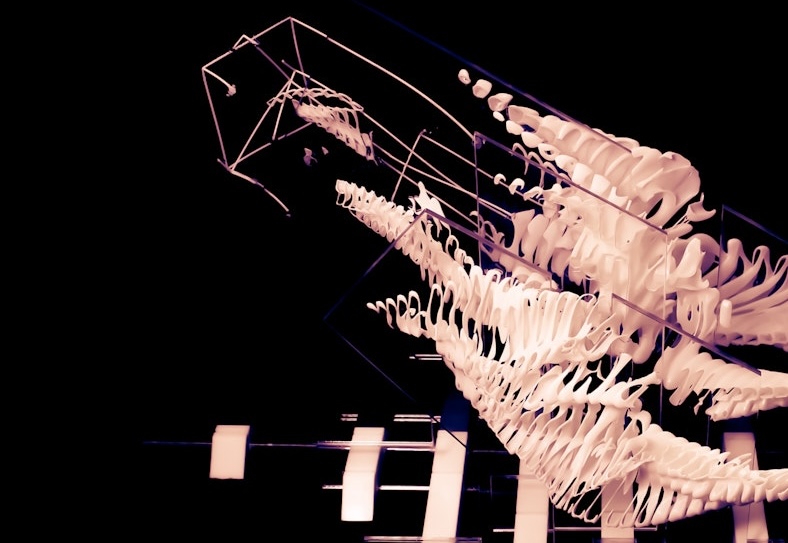

Currently nearing production, Carbon Cell's self-titled product is a protective and insulating lightweight rigid foam that's entirely plastic free.

Looking almost identical to expanded polystyrene but in a moody black colour, the foam was made from biochar – the blackened remnants of biomass, in this case crop waste, that is created when it is heated through pyrolysis.

This biochar is not only a renewable natural material, unlike the fossil fuels that form the basis of typical closed-cell foams, but it sequesters a good deal of carbon and continues to do so even after Carbon Cell is returned to the earth.

For every kilogram of Carbon Cell foam created, the company estimates two kilograms of carbon are removed from the atmosphere, turning a product category that is currently highly polluting into one that helps restore the environment.

A shortlisted candidate for Material Innovation in the Dezeen Awards 2025, Carbon Cell foam was invented by scientist Elizabeth Lee, engineer Eden Harrison and designer Ori Blich while they were studying at UK schools the Imperial College of London and Royal College of Art.

There, they became intrigued by the technical properties of biochar, including that it is lightweight, porous, insulative, adds strength and buffers moisture – just like expanded polystyrene.

To get it to a similar state, they followed a comparable production process, first mixing the biochar with bio-based polymers to make small, hard pellets and then heating them to make them expand like popcorn into a foam cell structure.

This is done using the existing expansion equipment for polystyrene and the foam can similarly be moulded into various shapes.

At the end of life, the natural polymer in Carbon Cell degrades in home composting conditions, leaving behind only the biochar, which keeps the carbon within sequestered for generations while enriching the soil.

Carbon Cell plans to start production in December on products for its first pilot projects and hopes to rapidly scale up in order to reduce the market for expanded polystyrene.

While this rarely recycled form of plastic has already been phased out in some forms of packaging, between seven and 12.8 tonnes of it is estimated to be produced annually, and the volume is rising.

It still dominates in areas such as drop protection for white goods, TVs and furniture, as well as in the construction industry – a key target for Carbon Cell.

"Our largest target market is building insulation – although it takes time to reach the scale and certification to enter this market with a viable product," said Lee, who is now CEO of Carbon Cell.

"On our way to achieving this, we are also preparing variations for use in acoustic panelling, interior design, thermal packaging, automotive composites, plant pots and even the film, TV and theatre industries, where lots of foam is used for scenery and props development," she told Dezeen.

The Carbon Cell team also has other plastic-based materials – including expanded polypropylene, polyurethane rigid foam and rigid polyiso foam – in its sights, as well as cardboard.

The company recently collaborated with British design studio Morrama on a project exploring applications and storytelling around its foam, the results of which were on show at the London Design Festival 2025.

As part of the collaboration, the team showcased a lamp made from its packaging as well as ring boxes and plant pots.

Another company working with biochar is German start-up Made in Air, which makes a bioplastic that can be used in building facades.

The post Carbon Cell makes plastic-free alternative to polystyrene appeared first on Dezeen.