Poured Earth is a sustainable construction method modelled on concrete casting

Material research studio Matter at Hand, founded by Assemble co-founder Lewis Jones, has created a prototype clay-based construction method named Poured Earth that emulates casting concrete.

Poured Earth was developed to make building with earthen materials easier and more accessible than when using materials such as rammed earth and cob, which are hailed for their sustainability but often labour-intensive.

Created by Matter at Hand as part of a residency at the Art in Manufacturing programme at the National Festival of Making, the Poured Earth project also explores how earthen construction methods could be scaled up by using a process similar to casting concrete, reusing much of the same equipment.

"Our use of concrete has shown how extraordinarily useful it can be to have a flowable, castable, solid material," Jones told Dezeen.

"The huge drawback of concrete is obviously its carbon footprint, and so being able to form and work with earth in a similar way could offer a very practical approach for rethinking how we build in the future," he continued.

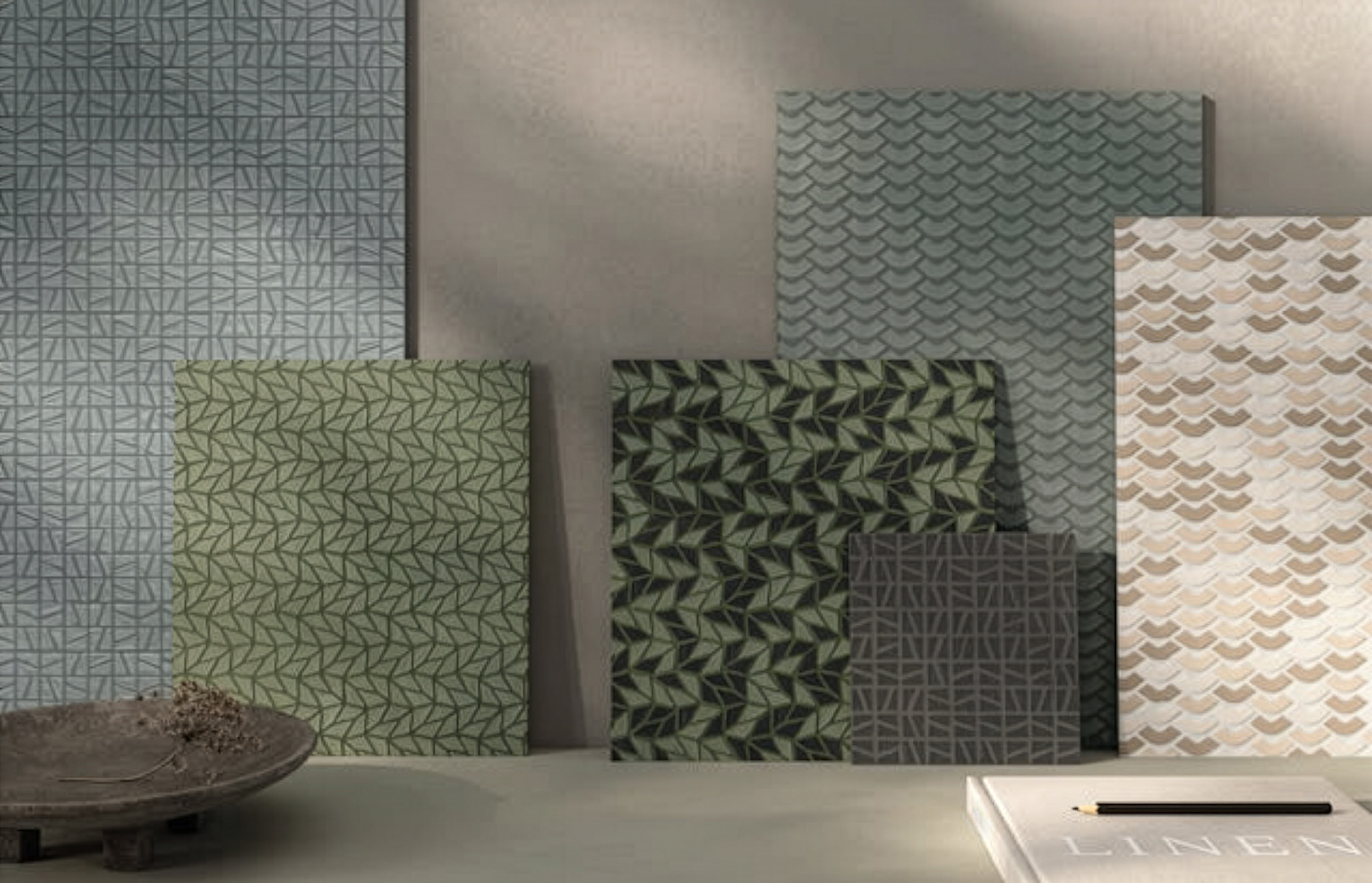

"Along with the scalability of this approach, it opens up new design possibilities for working with earth, allowing for a diversity of surface finishes and applications not usually associated with the material."

Similar to other earthen construction materials, samples of Poured Earth have so far been made by mixing clay with different quantities of sand, aggregate and natural fibres.

They are made without the need for a binder such as cement or gypsum, meaning they can be reformed or returned to the earth at the end of their life.

In a process akin to casting concrete, the materials are combined in a cement mixer and poured into formwork, which is vibrated to remove trapped air and left until ready to be demoulded.

Matter at Hand worked with ceramic manufacturer Darwen Terracotta when developing this technique, also building upon the company's slip-casting methods that it uses for architectural ceramics. Slip-casting is the process of pouring liquid clay into a plaster mould.

What sets Poured Earth apart from other earthen construction materials is the addition of deflocculants – a type of chemical agent commonly used in ceramic slip-casting.

By adding deflocculants such as sodium silicate, soda ash or bark tannins, the clay mix flows better without the need for additional water, resulting in a denser material and minimal shrinkage.

"The key difference is the use of deflocculants to create the flowing, fluid consistency that means it can be poured," said Jones. "Rather than having to add a lot of water, which reduces strength, increases shrinkage and drying time, deflocculants make a mix more fluid by changing the surface charge of clay particles."

"A few drops can transform a very thick, dense mix into a free-flowing liquid for pouring, whilst retaining its density," Jones continued.

"In ceramics, the use of deflocculants is really the foundation of slip casting, and a huge amount of knowledge exists in this area in the ceramic industry, but which hasn't yet made its way over to the world of earth construction."

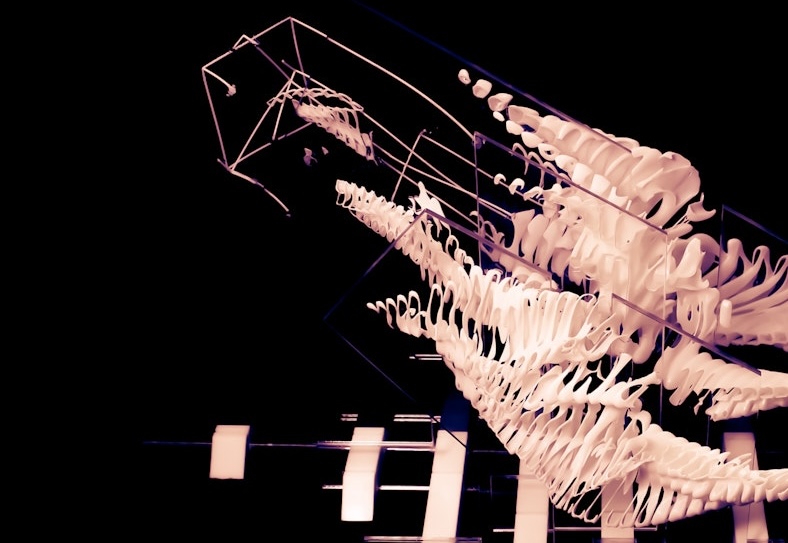

Samples of Poured Earth were exhibited at this year's National Festival of Making, which took place from 5 to 6 July at Blackburn Cathedral in England.

Matter at Hand reused moulds from Darwen Terracotta to cast the samples, using clay supplied by the manufacturer, combined with local waste aggregates and natural fibres produced in north-west England.

One of the exhibited pieces was a prototype structural Poured Earth wall that can be constructed in situ or as precast panels, made from clay, crushed ceramics and recycled construction aggregates.

A lightweight insulative panel set in a timber frame was made from a mix of clay, wood chip, hemp shiv and foamed recycled glass, while prototypes of hollow clay cast blocks were infilled with loose, natural insulation.

Matter at Hand also presented a composite wall comprising a 200 millimetre-thick internal load-bearing layer and a 250 millimetre-thick insulative layer, drawing on the CobBauge composite wall system.

Jones hopes to eventually develop the Poured Earth prototype into a full-scale building, offering an exemplar of how earthen construction can become a mainstream contemporary building method.

"In the context of the climate emergency, unfired clays offer so much, but there is a lot more we need to do to push earth construction back to being considered a mainstream building material again," said Jones.

"Partly this needs to come from a design perspective, showing all the incredible possibilities that these materials offer, and partly this needs to come from a practicality perspective – how to make these brilliant materials easier to use," he continued.

"This project seemed like a great opportunity to try and explore both of these elements, seeing how we can learn from knowledge in other fields to help drive new directions for earth construction and give us new ways of working with this age-old material."

Dezeen recently spotlighted the earthen material cob in our Building with Cob editorial series, which featured a deep dive into how to bring the material into the mainstream and a case study on the first home to be built with CobBauge.

The photography is by Lewis Jones.

The post Poured Earth is a sustainable construction method modelled on concrete casting appeared first on Dezeen.