Ten plastic alternatives designed to trump paper straws

US president Donald Trump has signed an order to abandon paper straws for single-use plastic. In light of his critique, we've rounded up 10 other examples of plastic alternatives that probably won't "break" or "explode". The executive order signed by the president on Monday stipulates that the federal government must fade out purchases of paper straws The post Ten plastic alternatives designed to trump paper straws appeared first on Dezeen.

US president Donald Trump has signed an order to abandon paper straws for single-use plastic. In light of his critique, we've rounded up 10 other examples of plastic alternatives that probably won't "break" or "explode".

The executive order signed by the president on Monday stipulates that the federal government must fade out purchases of paper straws for its own operations and advocates for the development of a National Strategy to End the Use of Paper Straws.

"These things don't work," Trump complained of paper straws. "I've had them many times, and on occasion, they break, they explode. If something's hot, they don't last very long, like a matter of minutes, sometimes a matter of seconds."

In response to the news, we've collected 10 alternatives to single-use petroleum-based plastic for the food industry, including a dissolvable drink bottle and reusable takeaway containers.

Biomaterials company Great Wrap created a bioplastic alternative to clingfilm that is made from leftover potato peel.

Although the company claims that the transparent packaging has similar textural and performance qualities to petroleum-based plastic clingfilm, it is compostable and designed to break down in soil within 180 days.

Find out more about this clingfilm ›

Designer Lucy Hughes won a 2019 James Dyson Award for MarinaTex – a compostable alternative to single-use plastic bags made from waste fish scales and skin.

"For me, a good design is something that bridges the gap between behaviours, business and our planet," she told Dezeen at the time.

Find out more about these bags ›

Notpla – a wordplay on 'not plastic' – is edible, biodegradable packaging made from seaweed and plants that was designed to replace fossil fuel-derived plastic altogether.

Since its inception as condiment sachets and a coating for cardboard takeaway boxes, Notpla has been used to create cutlery, food oil pipettes and laundry sachets.

Find out more about this packaging ›

Bioplastic Skin packaging by Valdís Steinarsdóttir

Bioplastic Skin is a project by Icelandic designer Valdís Steinarsdóttir, who turned waste skin from slaughterhouses into translucent bioplastic packaging for the animals' meat.

Her solution was designed to dissolve in hot water and biodegrade in a matter of weeks, offering an alternative to fossil fuel-derived single-use packaging.

Find out more about this packaging ›

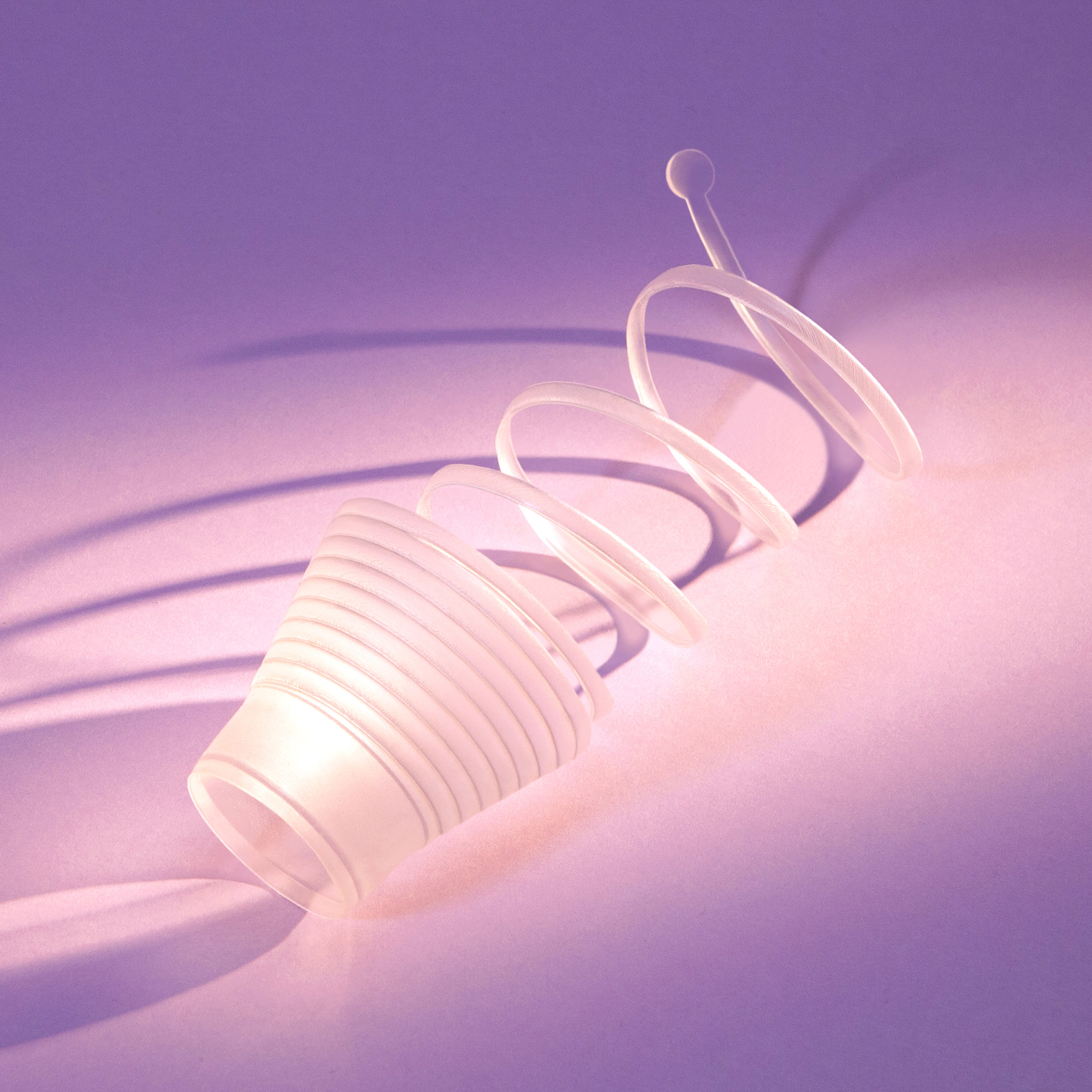

GoneShells bottle by Tomorrow Machine

Design studio Tomorrow Machine created a biodegradable juice bottle from a bio-based material made from potato starch that can be peeled away like fruit skin and then eaten, composted or dissolved.

Called GoneShells, the bottle is coated in a bio-based, water-resistant barrier on both sides to preserve the juice it holds.

"As long as you don't activate the degradation process by peeling the bottle or tearing it apart in another way, it works similarly to a traditional plastic bottle," studio founder Anna Glansén told Dezeen.

Find out more about this bottle ›

Zero packaging by PriestmanGoode

Zero is a reusable fast-food packaging concept by design studio PriestmanGoode.

The proposal suggests distributing bento-style stacked boxes made from mycelium, cocoa bean shells and pineapple husk without the need for individual lids, as each container is placed on top of another.

PriestmanGoode suggests creating a customer rewards system, where buyers pay a small fee to the delivery service for the packaging that would be reimbursed when the containers are returned to tackle the abundance of single-use food containers.

Find out more about this packaging ›

Bioplastic Skin packaging by At10

This bioplastic packaging was created by design studio At10 to hold ham slices and hot dogs, with a transparent appearance and texture similar to traditional plastic.

At10 created the material by boiling animal skins in water, which releases collagen and gelatin to create a flexible gel-like substance that can be moulded into "any shape desired" before hardening.

Find out more about this packaging ›

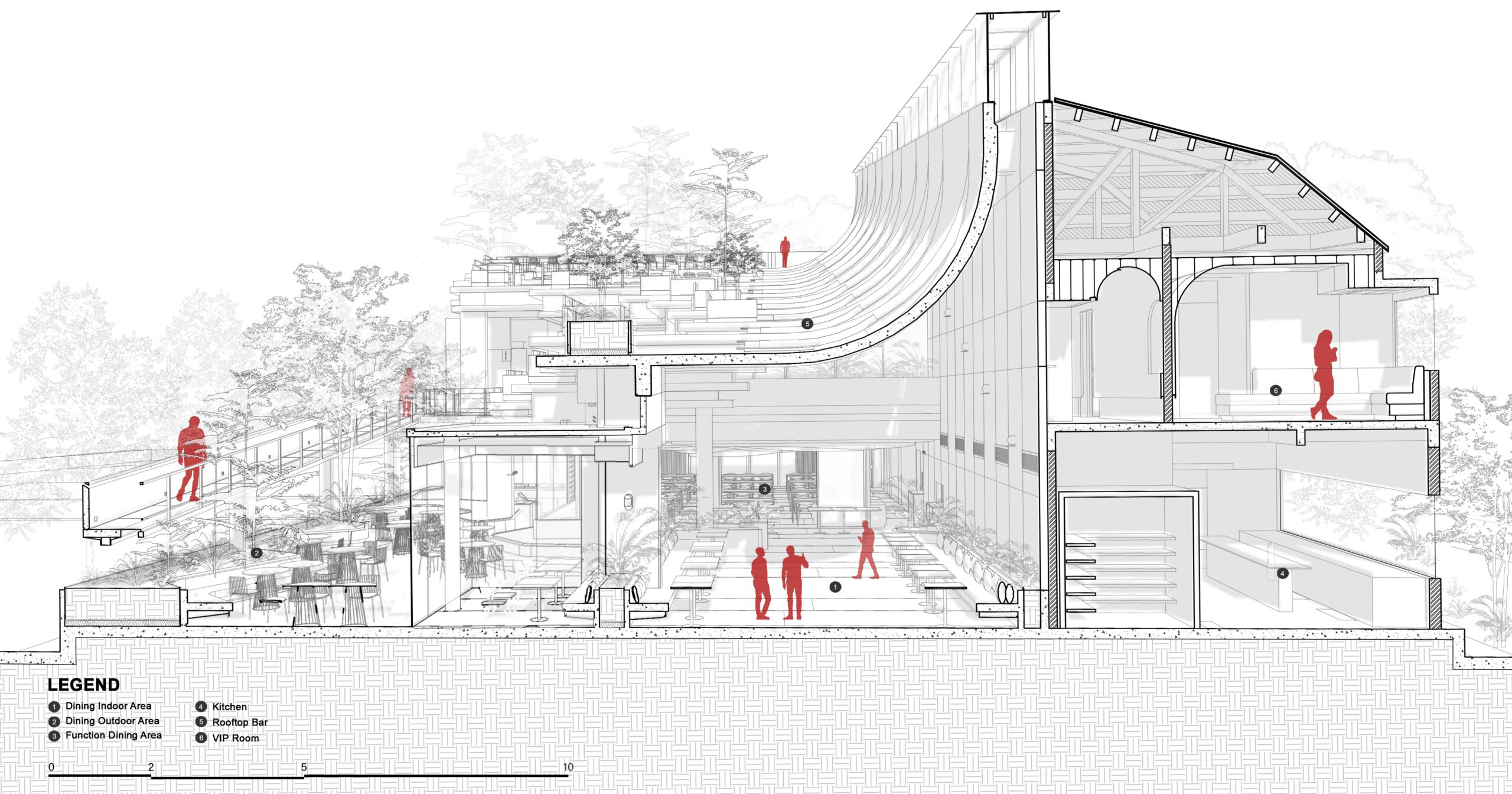

Chitofoam cups by Doppelgänger

Chitofoam is a bioplastic alternative to traditional expanded polystyrene (EPS) that is water-resistant, shock-absorbent and can be formed into cups, foam peanuts and other packaging.

Charlotte Böhning and Mary Lempres of Doppelgänger developed the material from the exoskeleton of plastic-eating mealworms to provide a backyard-compostable solution to wasteful EPS.

Find out more about these cups ›

Reuse packaging by Forest and Whale

Reuse is an edible food container made from wheat husks, which can be eaten or composted once users have finished their meal.

Created by design studio Forest and Whale, the container is most suitable for salad as it can't hold moisture for very long but contains no single-use plastic.

The container's lid is made from polyhydroxyalkanoates (PHA), a bacteria-based composite with properties similar to traditional plastic.

Find out more about this packaging ›

Dissolvable packaging by Holly Grounds

Designer Holly Grounds created dissolvable ramen packaging that turns into sauce during her time as a product design student at Ravensbourne University London.

The biofilm packaging consists of only a handful of readily available ingredients including potato starch, glycerin and water.

Grounds was motivated to develop the project after acknowledging the irony that instant noodles, designed to be cooked and eaten in under 10 minutes, come in packaging that takes upwards of eight decades to decompose.

Find out more about this packaging ›

The post Ten plastic alternatives designed to trump paper straws appeared first on Dezeen.