Nine times that Nike tried to transform footwear

Sportswear giant Nike has repeatedly sought to revolutionise footwear. In this roundup, we collect nine innovative projects from the brand covered on Dezeen.

Nike describes its recently launched Mind 001 trainer and Mind 002 mule as its "first neuroscience-based footwear".

The shoes, which were created using data collected from brain scans in the brand's new Mind Science Department, contain 22 foam nodes on the sole that move and compress underfoot, sending soothing messages to the brain.

"This is just the beginning," Nike chief science officer Matthew Nurse told Dezeen. "Once you understand how sensory feedback influences focus and recovery, that insight can shape everything – from training shoes that calm pre-competition nerves to recovery slides that help reset the mind after."

Find out more about Mind 001 and Mind 002 ›

Also recently unveiled by Nike was a prototype design for a motorised exoskeleton-like device that attaches to the lower leg and provides a power boost for running or walking by helping to lift the wearer's heel.

Developed in collaboration with robotics company Dephy, the product is still in still in the testing phase, with plans for a consumer version "in the coming years".

Find out more about Project Amplify ›

Released in 2021, the Go FlyEase can be put on or taken off hands-free thanks to a specially developed hinge system in the sole. Nike billed the trainer as an example of accessible design useful for people who might struggle to tie shoelaces.

It built on earlier shoes in the FlyEase range that used an openable heel.

Find out more about the GO FlyEase ›

Another example of Nike's attempts to change how we put on our shoes came in the form of the Hyperadapt 1.0 in 2016. These self-lacing trainers contain tiny electric motors and sensors that automatically tighten the laces when the wearer puts them on.

The shoes were inspired by the 1989 time-travel movie Back to the Future Part II, in which the protagonist Marty McFly is transported to 2015 and puts on a pair of Nike sneakers that tie themselves.

Nike later adapted the technology for a laceless basketball shoe, the Adapt BB.

Find out more about the Hyperadapt 1.0 ›

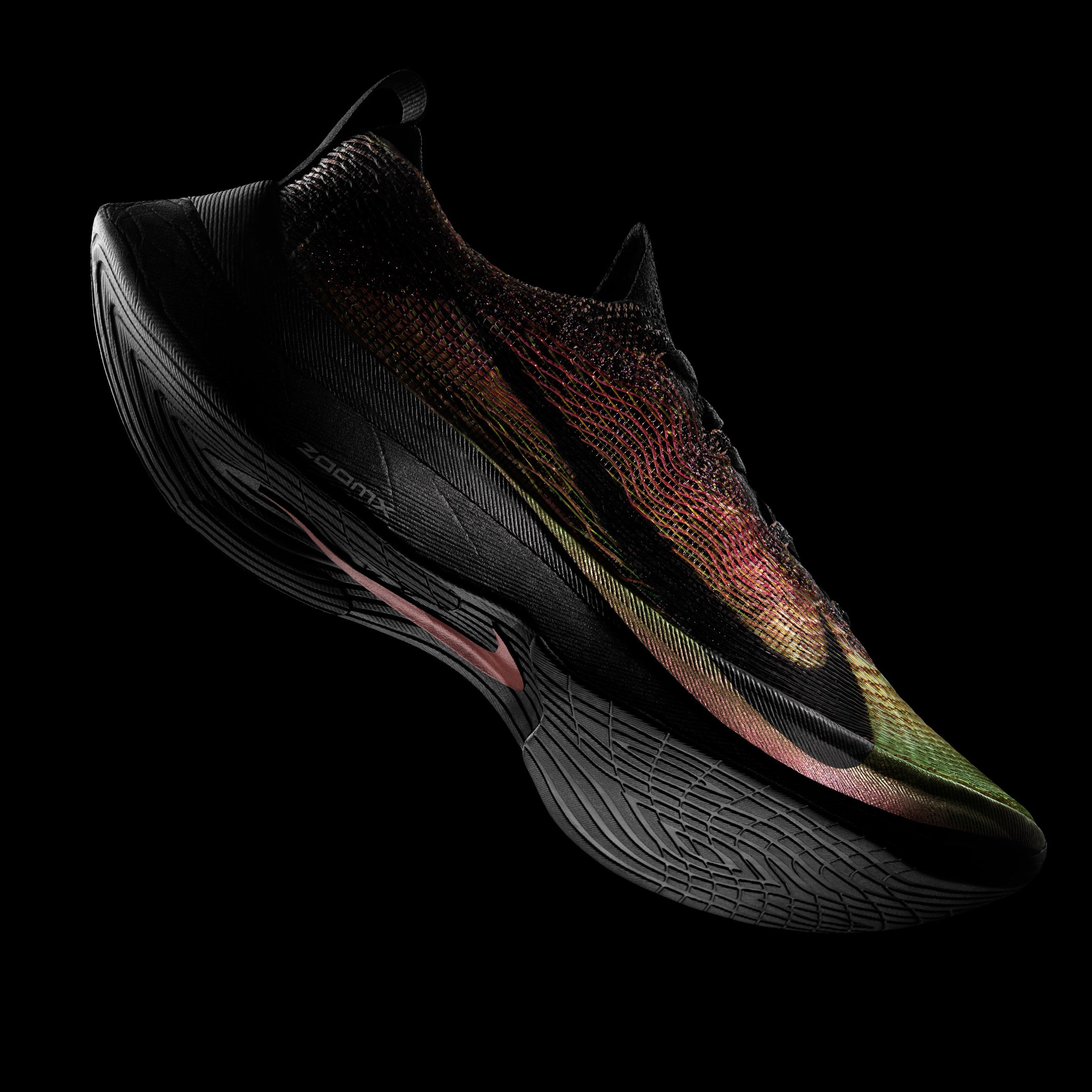

Possibly the most talked-about shoe ever made, Nike's Vaporfly triggered a revolution in running-shoe design. The brand began distributing prototypes to its elite athletes in 2016 to sensational results at that year's Olympic Games, and marathon world records were later smashed by runners wearing Vaporflys.

Featuring an extremely lightweight and extra-thick ZoomX foam sole embedded with a springboard-like carbon-fibre plate, the Vaporfly was so effective that some argued it provided an unfair advantage.

Dezeen has previously plotted a detailed timeline of the battle between Nike and its arch rival Adidas to develop the ultimate running shoe.

Find out more about the Zoom Vaporfly Elite ›

In 2004, the highly influential designer Marc Newson developed a shoe for Nike consisting of four interchangeable parts: an insole, an outsole, an inner sock and an injection-moulded outer cage perforated with holes.

Ahead of a 2014 reissue, Newson told Dezeen in an interview that it was "revolutionary" as one of the first times a shoe had been manufactured in a mould rather than stitched together like a garment.

Then-Nike CEO Mark Parker told Dezeen that the Zvezdochka had been an important step in other footwear breakthroughs at the company.

Find out more about the Zvezdochka ›

Working with health-tech company Hyperice, Nike last year unveiled a boot that massages the wearer, intended to help athletes warm up and decompress.

Air "bladders" inside the shoe inflate and deflate to massage the foot and ankle, with heating elements to help target achy tissue.

Power comes from a battery in the sole, while a button on the heal adjusts the level of compression and warmth.

Find out more about the Hyperboot ›

Almost all shoes are nearly impossible to recycle, because it's very difficult to separate them into their constituent materials.

Nike – which is the world's biggest producer of shoes – took a step towards addressing this issue with a pair of modular trainers that can be easily disassembled. Instead of being held together by glue, they consist of three interlocking parts.

However, in a later interview with Dezeen, Nike chief design officer Martin Lotti said that material choice is more important to reducing the environmental impact of the company's footwear products.

Find out more about the ISPA Link ›

In 2012, Nike developed Flyknit. This technology combines strands of polyester yarn to produce shoes with lightweight, almost seamless uppers that feel like a sock and are made in one piece to reduce manufacturing waste.

Nike began applying Flyknit to many of its sports shoes, and it formed the upper for the aforementioned Vaporfly Elite. Despite enjoying huge success with that shoe, Kenyan marathon runner Eliud Kipchoge had one piece of feedback: it absorbed water, meaning the shoe got heavier during the race.

In response, Nike's designers came up with Flyprint for Kipchoge's shoes at the 2018 London Marathon. Instead of being woven from fabric, it was 3D-printed from a plastic filament. The brand claimed they were the first running shoes in the world to have 3D-printed uppers.

Find out more about Flyprint ›

The photography is courtesy of Nike.

The post Nine times that Nike tried to transform footwear appeared first on Dezeen.