"It's been a very stressful year for all US manufacturers" say furniture companies

Ahead of potential rises in furniture tariffs in January 2026, manufacturers are preparing for the continued "economic uncertainty" of imports under the current trade policy in the United States. Dezeen asked furniture companies how they are dealing with the changes.

A host of tariffs rolled out by US President Donald Trump has left furniture companies and their manufacturing arms scrambling to navigate changing prices on imported goods as the holidays approach.

"Tariffs are rapidly changing"

"It's very hard, as you can imagine, to make long-term decisions in this climate," office furniture manufacturer Humanscale CEO Bob King told Dezeen. "Tariffs are changing rapidly every few weeks. Our people in operations have worked 60-hour weeks, sometimes more, just dealing with this."

"It's been a very stressful year for all US manufacturers."

Currently, a furniture tariff implemented in October 2025 ranges from 10 per cent to 25 per cent for items such as soft-wood and upholstered furniture, respectively, but is set to rise to as much as 50 per cent for certain items starting in January.

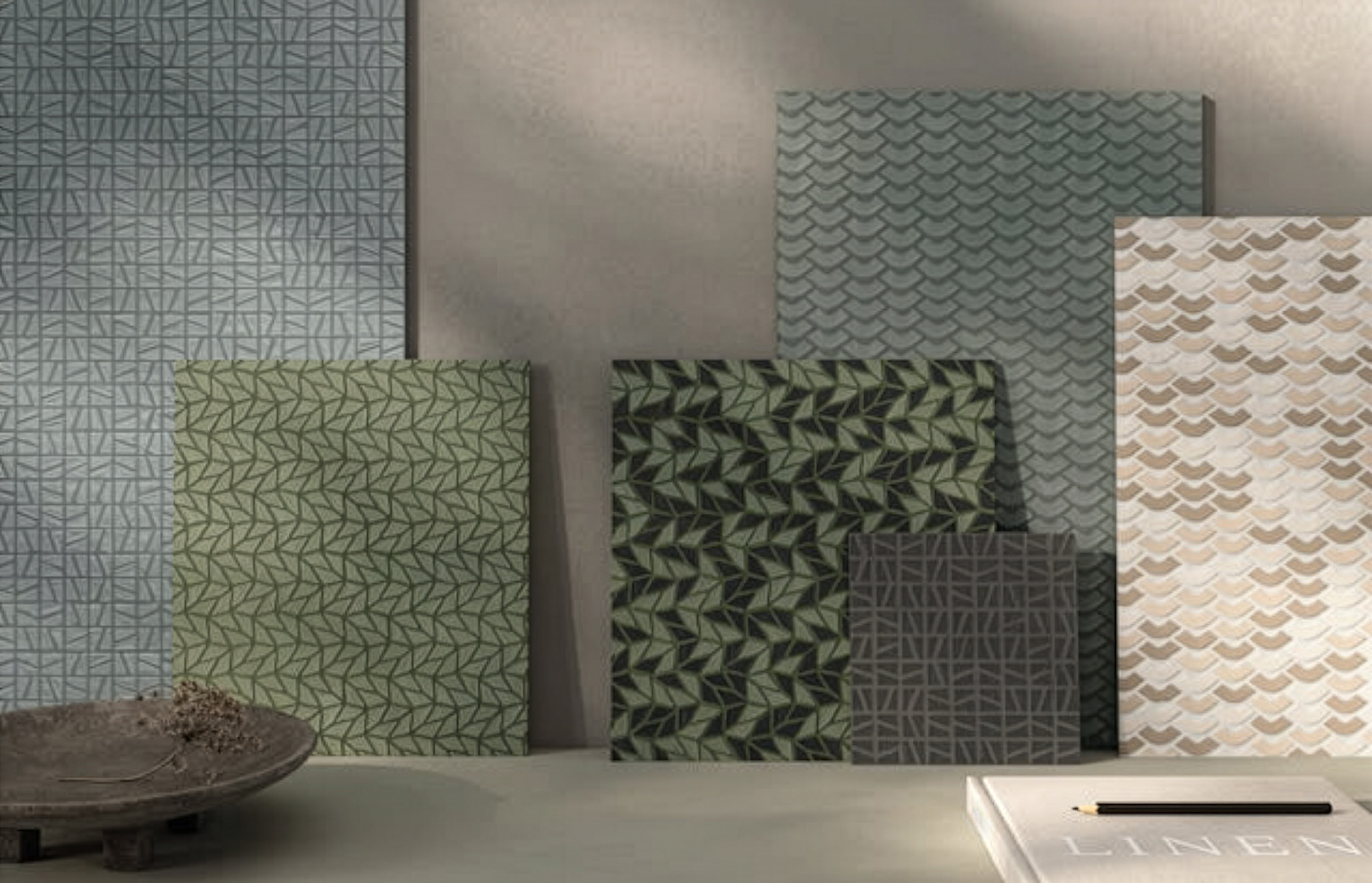

This tariff, along with others such as on imported metals and textiles, has left furniture companies and manufacturers that do business in the US to monitor, understand and adjust to rapidly changing prices on imported materials.

At this year's October trade fair in High Point, North Carolina, the country's most concentrated exchange of home furnishings, this meant that quoted prices changed in a matter of days, according to the Economist.

However, despite price rises, large manufacturers such as La-Z-Boy saw relatively little change in volume year over year.

Affordability an "absolute priority"

Furniture brands have had to strike the right balance between the rising costs of manufacturing goods and affordability for customers and clients.

"Being affordable for the many people remains an absolute priority for IKEA, especially in times of economic uncertainty and rising living costs," a spokesperson for Swedish company IKEA told Dezeen.

"We believe a stable and open global trade environment helps support lower prices for people, and we remain committed to providing affordable, quality goods to the many in the US. Due to the new economic reality, we've made necessary price adjustments while actively working to reduce the impact on our customers."

"We will continue aiming to lower prices whenever and wherever possible."

Large furniture companies that do produce in the US generally assemble pieces by combining parts sourced from several national and international producers. In large companies, a single chair is rarely assembled using all domestic products.

For instance, while furniture brand HBF manufactures domestically in North Carolina, they source odds and ends, such as foam backing and metal components, mostly§ from Canada.

Although the company primarily produces in the US, it's still affected by import tariffs, said general manager and vice president of HBF and HBF Textiles Casey Baxter.

"We partner with a lot of European mills, and they're the ones that are predominantly doing a lot of our higher-end goods," Baxter told Dezeen. "Tulles, velvet – just more premium materials are coming from predominantly European mills".

"But even if [a textile] is domestically woven [in Europe], it doesn't mean that the yarns are domestically sourced. There's still a surcharge being passed along for that. Some of those mills have given us small increases for surcharges of their own, because they're getting yarns from international suppliers."

While manufacturers pay a portion of tariffs themselves, rising prices for them can mean rising prices for the customer and client, which is another adjustment to navigate.

HBF, like many firms, has placed a three-per-cent surcharge on its furniture and a five-per-cent surcharge on its textiles, for now. It's part of a larger wait-it-out strategy to avoid folding the cost of tariffs into raising the base price of its goods.

"It's a freaking nightmare"

"Any customer that's buying an HPF furniture item right now is also paying a three-and-a-half per cent surcharge, which is directly related to the tariffs," said Baxter.

"We didn't want to [adjust] our price list based on something that might be temporary. [The tariffs] could go away next year. So that's why we're implementing a surcharge, versus taking a price increase and making it permanent."

Ultimately, furniture companies must monitor tariffs "every day", according to Baxter, with the assumption that dramatic changes are ahead for the new year.

"It's a freaking nightmare," said King.

Both Baxter and King said bringing manufacturing and sourcing completely domestic to avoid tariffs would be nearly impossible, and according to Furniture Today, manufacturing in the sector has been contracting since the tariffs were announced.

"[The US] is not set up for manufacturing," said Baxter. "It would be years to actually set up some of that supply chain. We just don't have that infrastructure here at all."

"We're just not good at certain things anymore because we've chosen to outsource it."

US companies such as Costco have sued the Trump administration over the tariffs, with the case currently sitting in the US Supreme Court and updates expected this month.

According to the Home Furnishings Association (HFA), "the industry awaits the Supreme Court's ruling" in order to see if furniture manufacturers may also be able to receive refunds for the rising cost of imports on their own business.

"This situation is evolving rapidly, and many regulatory interpretations remain unclear," said the HFA in a statement.

"As new information becomes available and the formal processes begin to take shape, HFA will continue to provide timely updates to help retailers understand their options and prepare for any potential impacts.

The photography is by Jan van der Wolf.

The post "It's been a very stressful year for all US manufacturers" say furniture companies appeared first on Dezeen.