Design Museum pushes for stone construction in the UK with Stone Demonstrator

Stone makes up the facade, frame, foundations and floor slabs in the Stone Demonstrator, a project by London's Design Museum aimed at getting the British construction industry to embrace the "ultra-low-carbon" material.

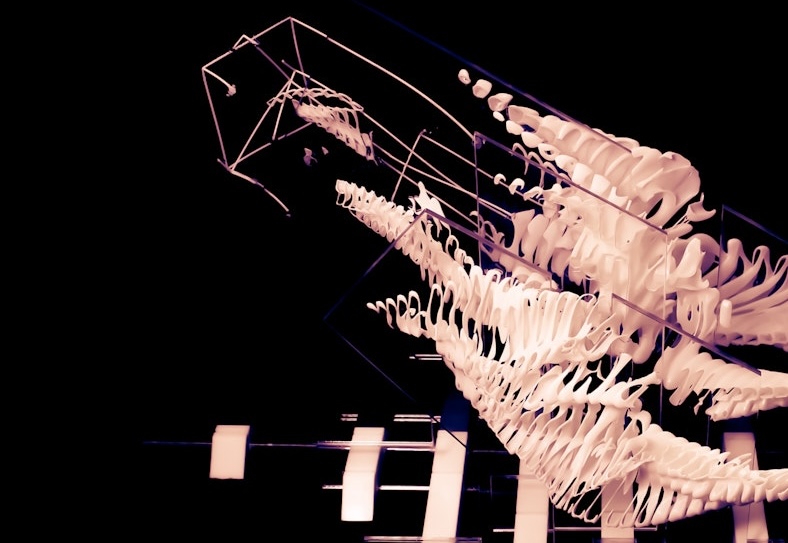

A traditional but these days sometimes overlooked structural material, stone is given centre stage in the Stone Demonstrator, a 1:1 scale prototype of a section of a small housing block erected at Empress Place within West London's Earls Court development.

The stone displaces all of the concrete and fired clay brick and nearly all of the steel that would normally be used in this everyday style of building, reducing the carbon emissions by around 90 per cent.

The project is the work of the Design Museum's Future Observatory – a research programme dedicated to catalysing the green transition – along with architects Groupwork and engineers Webb Yates and Arup, who regularly use structural stone.

Groupwork founder and chairman Amin Taha said that the demonstrator was intended to show the local construction industry how straightforward it is to build with stone, using existing products and working to standard codes.

"Its purpose is not to promote stone for sentimental reasons but as an ultra-low-carbon alternative to reinforced concrete and steel structures clad in fired clay bricks," said Taha.

"At 90 per cent less embodied carbon and the same price as concrete and steel frames and fired clay bricks, it's the ethical choice," he continued.

The Stone Demonstrator's stone components start with the foundations, which were made of simple reused stone blocks from a decommissioned bank in the city that were used in a manner similar to the footings of historic buildings.

Above that, there is a frame designed by Webb Yates and Arup. This was made using a newer approach to stone construction, with stone blocks that are pre-tensioned into beams and columns and then dropped into place on site.

With this method, steel tendons are passed through the cavities in the stone and compressed by steel plates to make secure building elements that also have the benefit of being disassemblable and reusable in the future.

This type of frame is not strictly necessary for a structure of three storeys, but Taha and Webb Yates associate director Liam Bryant indicated that it could be used in place of the reinforced concrete or steel frames in buildings of up to 80 storeys.

For flooring, the Stone Demonstrator offers two slab options: one is another pre-tensioned stone solution – much like the frame but in a different shape – and the other is a new hybrid timber and stone product.

Invented by Webb Yates and now in production by German company Bamberger, it involves stone slabs fixed on top of dowel-laminated timber (DLT).

All of these components replace concrete, which Future Observatory director Justin McGuirk said he has come to think of as "the ultra-processed food of the construction industry" – a modern convenience but one that did not improve on the raw option.

"Concrete is stone that you dug up, crushed, burned, mixed with other stone, dredged sand from probably under the sea, mixed with water and chucked in the back of a lorry that has to spin at a regular rate," added Bryant.

"Stone construction is the same material. You dig it out of the ground, you cut it into pieces, you maybe put some rebar in it," he continued. "It's one-third of the process."

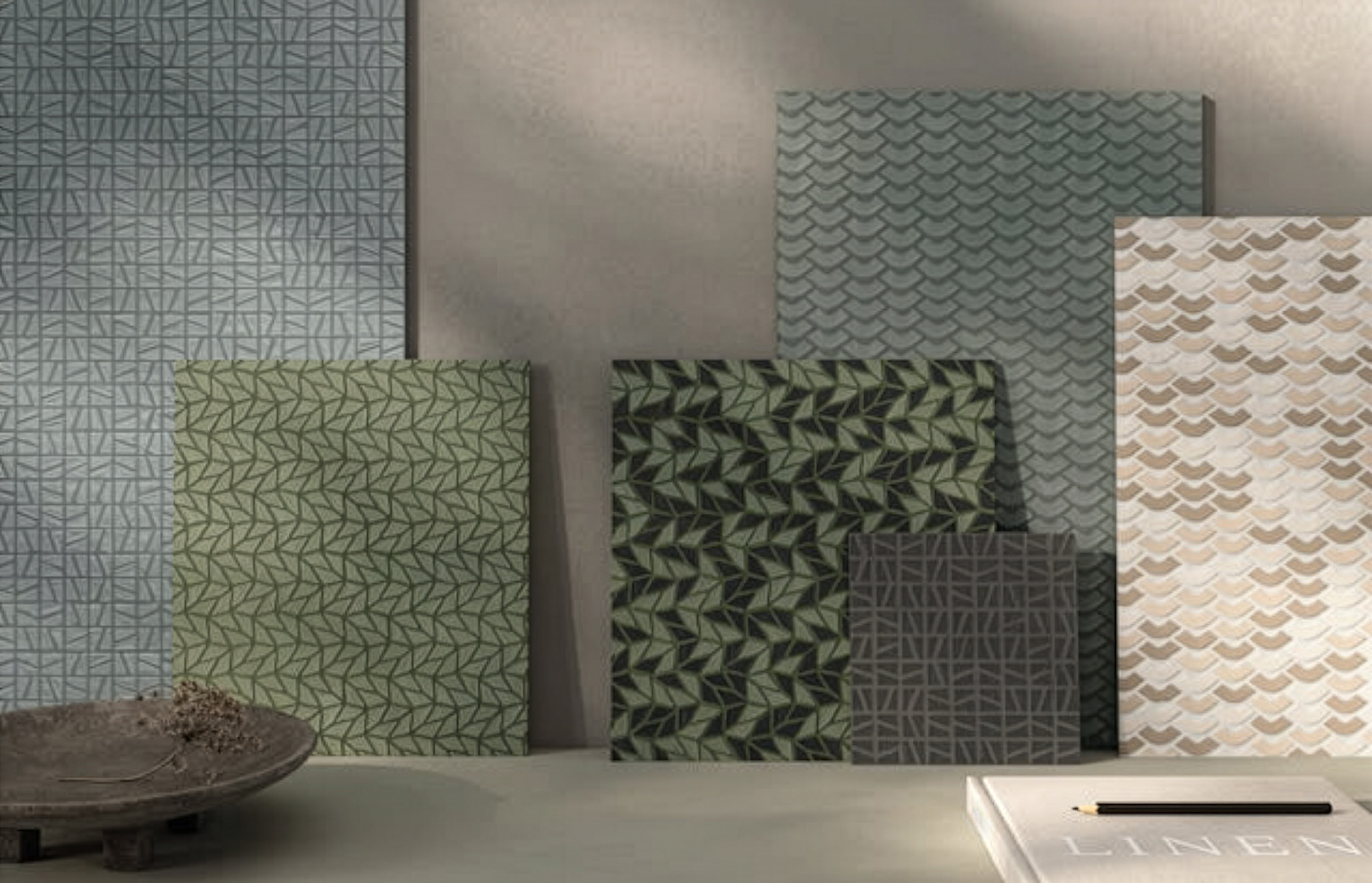

In addition to targeting steel and concrete, the Stone Demonstrator takes aim at fired clay bricks, the London vernacular for exterior walls, with a self-supporting facade of bricks cut from raw stone.

While clay bricks are rarely given the same amount of scrutiny in terms of sustainability, the stone bricks are again 90 per cent lower in carbon emissions, the Stone Demonstrator team said – a huge potential saving given that as many as 2.5 billion bricks are used in the UK annually.

In total, the Stone Demonstrator team's calculations show that an equivalent structure built using a steel frame with a clay brick facade would emit around 40,000 kilograms of carbon dioxide, while one with a frame made of reinforced concrete would emit 32,000 kilograms.

By contrast, the Stone Demonstrator produced 3,000 kilograms of carbon dioxide.

Dezeen took an in-depth look at stone as a potential low-carbon, modern structural material in the Stone 2.0 content series in 2024.

While many experts spoke in favour of the material, architect and researcher Natalia Petkova emphasised that it must be properly selected, sourced and transported.

The photography is by Bas Princen.

The Stone Demonstrator is expected to remain at Empress Place until at least June 2026. See Dezeen Events Guide for an up-to-date list of architecture and design events taking place around the world.

The post Design Museum pushes for stone construction in the UK with Stone Demonstrator appeared first on Dezeen.