AA Design & Make students devise simple way to build with tree forks

Students from London's Architectural Association have developed a low-cost and easily repeatable way to build with tree forks – a type of timber that is usually discarded as waste even though it is unusually strong.

The project, titled A Forest Datum, saw the students design and build an elevated forest walkway by cutting the tree forks using a simple but adaptable jig.

The jig trims the irregularly shaped tree forks to workable dimensions while still maintaining their structurally advantageous Y shape.

The project took place within the AA's Design & Make course, which sees staff and students live and work within the industrial woodland of the university's Hooke Park satellite campus in Dorset, England.

There, the students are challenged to work with the site's waste streams and test new ideas by fabricating experimental structures at full scale.

In previous years the course has also involved low-value timbers, but co-director Emmanuel Vercruysse told Dezeen that the staff had pushed the challenge further for the 2025 cohort by focusing on small forking branches.

"We know that forks are, from an engineering point of view, the strongest part of the tree, because all the grain is completely intertwined," said Vercruysse.

Usually, these parts of the tree are left on the woodland floor during industrial harvesting, but for this project, the foresters obtained them through high pruning, leaving the rest of the plant in good health.

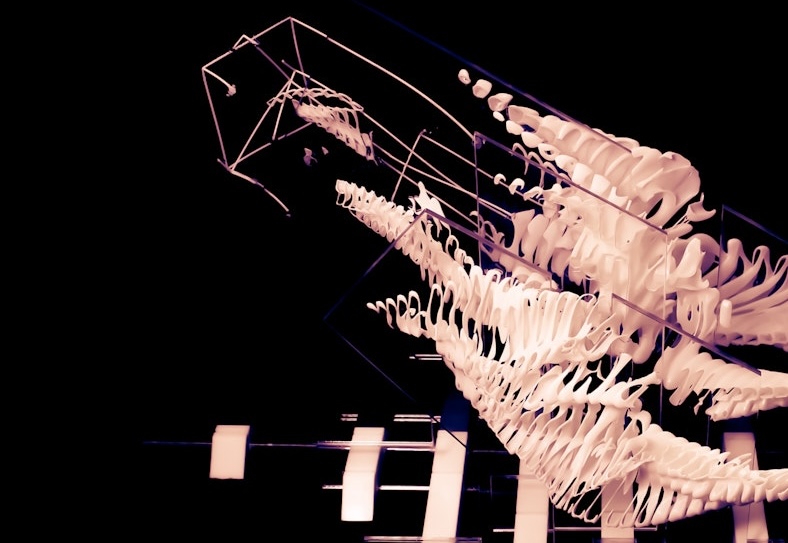

To work with the irregularly shaped forks, the students conceptualised each one as diagonally filling an invisible block of the same size and shape.

These blocks would be stacked against other to make a flooring structure with the forks supporting each other in a long zigzag. With this method, the tree forks can vary in shape, as long as their ends are cut in line with the block edge.

To trim the forks precisely, the students devised the jig, which is essentially made of three planks of wood and several adjustable 3D-printed connectors to hold the fork in place.

A sled jig, it slides along tracks beside a band saw to enable quick and precise cutting.

To create the walkway, the forks are pressed diagonally against timber battens and pulled tight with a tensioning system of Dyneema cables to secure the structure. The tension can be relieved to free the parts for disassembly.

Vercruysse said the Forest Datum process is "highly repeatable". It is also intentionally low-tech, even though the Design & Make staff have previously oriented towards robotics, so that it can be applied even in potentially low-income countries.

"We are really excited about this project because the material is widely available," said Vercruysse. "You don't need any funding for it. The only thing you need is a community to build it, a bandsaw and a jig."

He said the method can be used to make roof, floor and wall structures, anywhere where there is a forest.

"We don't have to lug a 500-kilo, six-axis robotic arm with us," he said. "All the intelligence sits in the jig. And that's, I think, the genius of the project.".

He hopes that the work the AA is doing at the Hooke Park campus will drive a rethink in how timber is used. Currently, he said, using just 50 per cent of a standing tree would be seen by the timber industry as highly efficient, but that amount is not sustainable

"Everyone says timber is going to save our built environment, but there's just not enough timber to go around to do that," he said.

At Hooke Park, they are now managing to use about 80 per cent of the tree, he estimated.

They used beech for the forks and cedar for the other components of the 15-metre walkway, although those woods were purely selected for testing purposes and are not the ideal species for durability.

The Design & Make course has also previously worked with forked branches to build a barn in 2016, although that involved a more high-tech process where every fork was 3D scanned to determine the arrangement.

They have also used steam-bending techniques to create a lattice-framed shelter.

Project credits:

Design + Make 2023-25 students: Yan Chen, Yonger Chen, Paola Gonzalez Ferreiro, Seongsoo Han, Alejandra Marcovich, Kavana Irappa Pujar, Ramtin Taherian, Mingxin Yang, Ramsey Young

Design + Make staff: Kate Davies, Emmanuel Vercruysse, William Gowland, James Solly , Wyatt Armstrong, Sam Turner Baldwin

The post AA Design & Make students devise simple way to build with tree forks appeared first on Dezeen.