"Ancient cooling techniques" allow 3D-printed partitions to regulate temperature

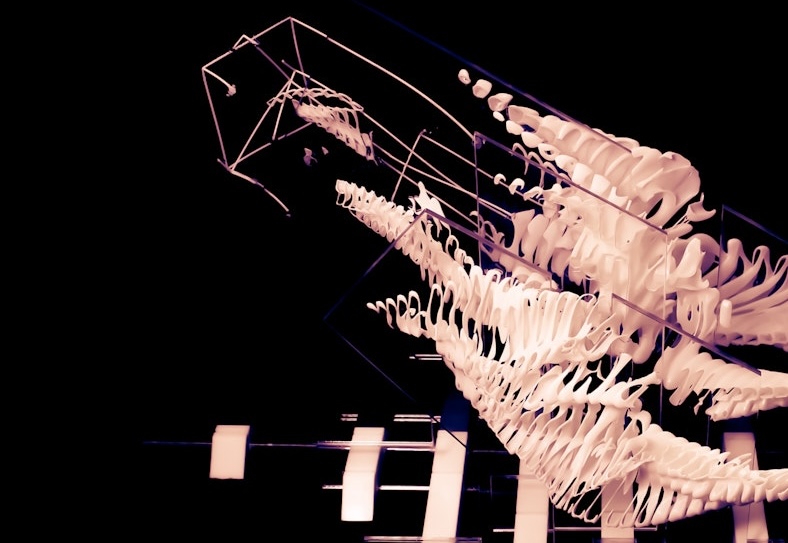

A team of researchers at US university Virginia Tech has developed a concept for a 3D-printed, evaporative cooling system made of hollow clay columns that can be filled with sand and water.

The system, which can cool the surrounding air by up to 10 degrees Fahrenheit (5.56 degrees Celsius), has been formatted into a wall partition and is currently undergoing testing.

It could also be formatted into different interior objects, such as a "cooling chair" made from the same materials. The hollow clay brick could also form the basis of a cooling building facade, a bit like a breeze block.

"The beauty of this technology is you have free cooling, all you need to do is put water through it," said Stefan Al, an architect, urban designer, and assistant professor of architecture at Virginia Tech, who came up with the concept.

The columns function by having warm air pass through them, where water stored in the internal sand will evaporate, working to cool the air that passes through it.

To develop the concept, the architect collaborated with Brook Kennedy, an industrial designer and fellow faculty member at Virginia Tech, who in 2019 designed a passive water-harvesting system called the Fog Harp.

Al envisions the system cooling system as a hybrid between the muscatese, a type of evaporative window design that originated in Oman, and the zeer pot, a centuries-old cooling device that acts as a fridge by placing a smaller clay pot inside a larger one and filling the space between them with water that ends up evaporating through sand.

Al's research is based on knowledge from these ancient techniques. The underlying principle – that water absorbs heat as it evaporates, which lowers the temperature – has been harnessed for at least 4,500 years.

Ancient Egyptians used wind catchers in combination with evaporative water systems. In the Middle East, people filled porous clay jars with water and placed them near latticed windows, so the air passing through the window would help the water inside the jar evaporate and cool the air inside the home.

These techniques are still in use in parts of the world today.

But since the advent of electricity ushered in mechanical air conditioning, they have largely fallen out of favour in the Western world, said Al.

"We're trying to get the best of those types of ancient techniques but put them in a modern context and see how we could optimize it further," he told Dezeen.

Optimisation is key since the day-to-day operations of buildings today – heating, cooling, lighting, and appliances – are responsible for more than 30 per cent of global energy consumption and around 26 per cent of greenhouse gas emissions.

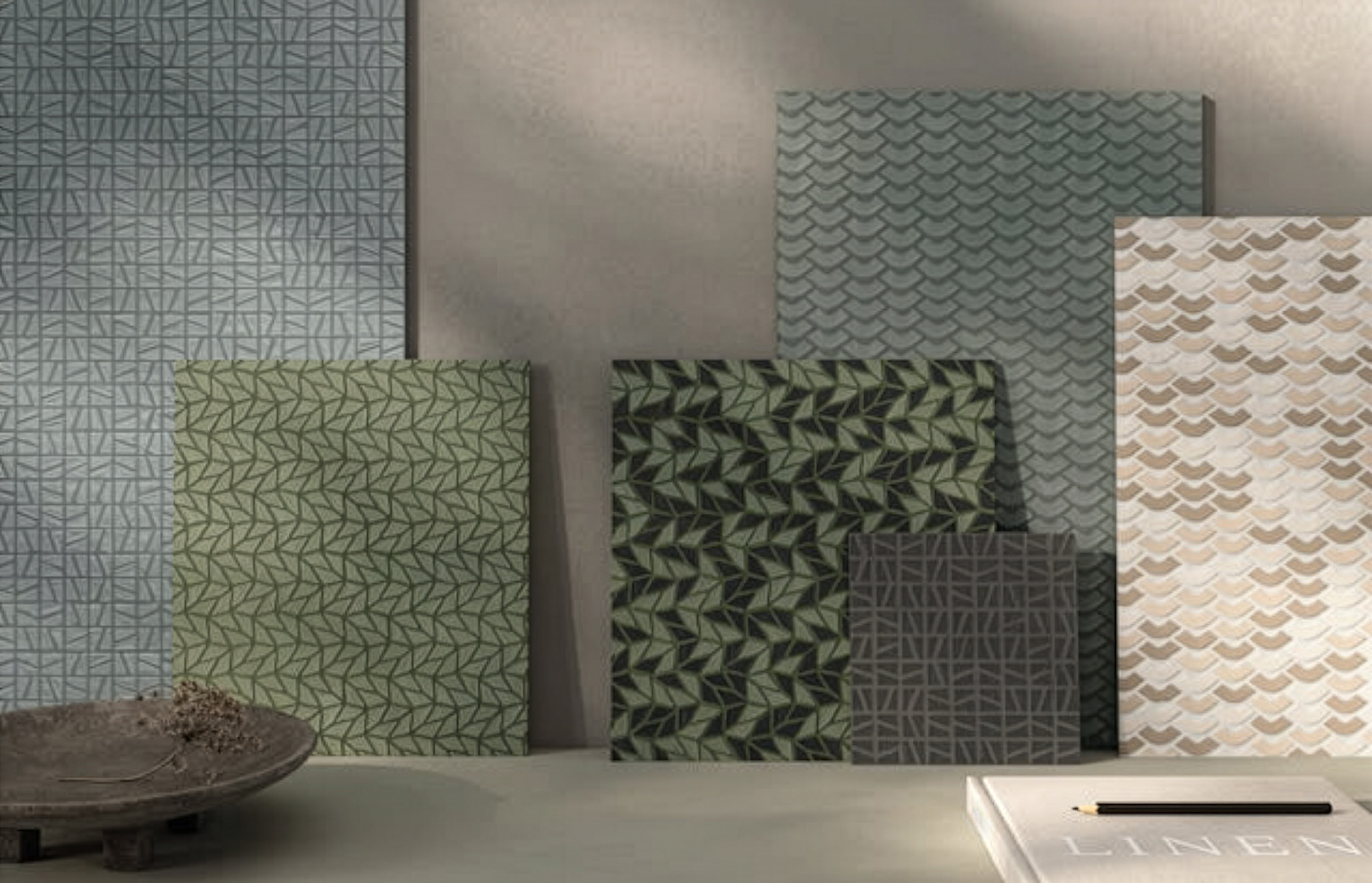

For Al, what distinguishes this new system from previous passive cooling strategies is the evolution of 3D-printing technology and the ability to print with materials beyond concrete. Clay has a lower embodied carbon footprint compared to cement-based products.

It also stores and releases heat, making it ideal for passive thermal regulation.

To date, the team has printed three different prototypes of various cylindrical shapes, then measured their thermal performance using infrared imaging. Al said the passive cooling effect varied based on each column's geometry and surface texture, which together determine the total evaporative surface area.

The porosity of the material is another critical factor, as it needs to allow enough water to pass through and evaporate without compromising the structural stability of the clay columns.

To fully test the system's performance, the researchers will need to build an entire room. For now, their prototypes are constrained by the size of the kiln at Virginia Tech, which allows them to make clay objects no larger than a vase.

Al said the cooling effect is most noticeable when the system is paired with a fan or placed in a space with strong natural airflow. Due to the localized nature of evaporative cooling, the air closest to the structure will feel cooler, making it less effective than conventional air conditioning, which disperses cool air more uniformly across a room.

Still, Al believes the system could be useful in targeted applications – such as wrapping around a seating area to create a cool microclimate. It helps that it is aesthetically pleasing, too, he said.

"In contrast to AC, which is always hidden, this could be beautiful, and could be seen, and raise people's understanding and appreciation of these old techniques that are much more sustainable in making us feel comfortable."

With summers becoming increasingly hot across the world, architects and designers have been working to create energy-efficient cooling systems. Some recent examples include water-filled glass facades and solar-reflective pavement paint.

The post "Ancient cooling techniques" allow 3D-printed partitions to regulate temperature appeared first on Dezeen.