Aircela demonstrates prototype device that "produces gasoline directly from air"

Tech company Aircela has revealed what it claims is the first working machine in the US that produces gasoline from air, bypassing the need for fossil fuels with a prototype the size of a large refrigerator.

Demonstrated in late May on a New York City rooftop, Aircela's machine creates petrol by combining carbon dioxide obtained through direct carbon capture and hydrogen produced by electrolysing water.

This type of synthetic fuel, or "synfuel", is fossil-free and carbon-neutral if made with renewable energy, because the amount of carbon dioxide it releases into the atmosphere is the same as the amount that is captured.

It is also drop-in compatible, meaning it can be used in existing engines just like regular petrol or gasoline.

While air-to-fuel technology might sound too good to be true, it has been in development at universities such as Cambridge and companies such as Bill Gates-backed Carbon Engineering. Their focus, however, has been on large-scale operations, particularly with the view to service the aviation sector and other heavy industries that are difficult to electrify.

Aircela has instead accelerated development by focusing on creating a small machine rather than a centralised model of production. This has avoided the need for substantial upfront investment in new infrastructure.

"By designing compact, modular machines, we can produce fuel directly where it's needed, reducing transportation costs, simplifying logistics, and enabling production even in remote or hard-to-fuel locations," Aircela head of industrial design Liz White told Dezeen.

While the market for this kind of small machine is still developing, Aircela imagines that several of the modular units will be able to be linked for mass production.

"By producing many smaller units, we're able to drive down costs much faster than a traditional centralised plant would allow," continued White. "This approach lets us scale manufacturing, continuously improve the technology, and bring fossil-free fuel to market more quickly and efficiently."

In choosing to focus on what is effectively a consumer device, Aircela had to give substantial thought to product design and user experience.

According to White, the product was designed entirely in-house with an emphasis on thoughtful form language and intuitive ease of use.

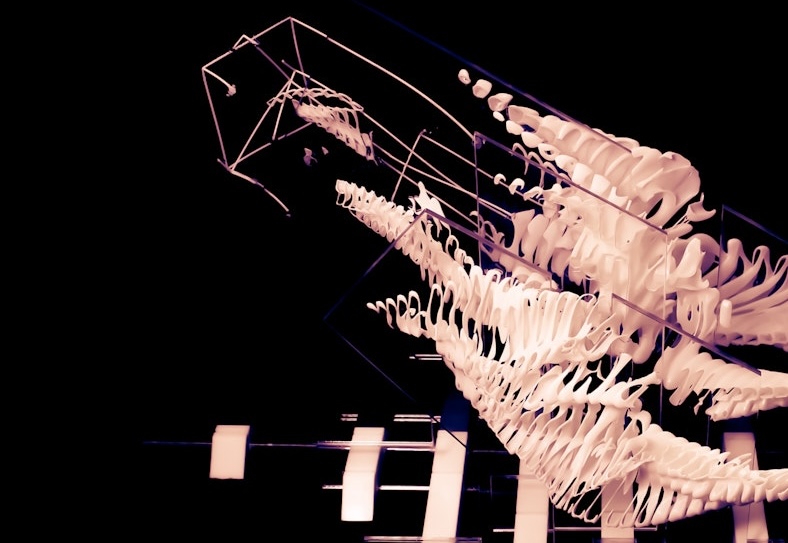

The machine is devised as three connected modules. Each one represents one of the core stages of the air-to-fuel process – carbon capture, electrolysis and fuel synthesis – and has a hexagonal shape drawn from nature and bees.

"Our hexagonal modules are inspired by hexagons found throughout nature, for their stable bond angles, strength, and space-saving efficiency," said White. "This lends to agile scalability for different applications, and the ability to 'honeycomb' multiple units."

"We also love honey bees, and we hope the nectar of our Aircela machines will serve our ecosystems comparably," she added.

The machine is completed with a custom fuel nozzle and dock that replicates the experience of pumping petrol at a service station and a colour palette that represents the machine's three inputs of air, water and sunshine for energy.

The top hexagon module is the one responsible for carbon capture and uses a liquid sorbent solution that binds carbon dioxide. The sorbent is continuously reused and regenerated within the machine, according to Aircela, so it does not need to be replaced.

The hexagon on the bottom left is where electrolysis splits water into hydrogen and oxygen. The hydrogen is stored while the oxygen is safely released into the atmosphere.

In the module on the bottom right, the stored carbon dioxide and hydrogen are combined to produce methanol, and the methanol is then converted into petrol using a chemical process known as methanol-to-gasoline.

According to White, an Aircela machine operating 24-7 would produce approximately one gallon (4.55 litres) of petrol in one day.

Aircela was founded in 2019 by Mia and Eric Dahlgren and its investors include Maersk Growth, a division of Danish shipping company Maersk. Shipping is one of the industries that could be decarbonised if Aircela succeeds in its mission.

New York City also witnessed another display of carbon conversion technology in May with the Airco "pop-up store", which exhibited products representing industries that could be transformed through the use of synfuel.

The post Aircela demonstrates prototype device that "produces gasoline directly from air" appeared first on Dezeen.