The Future is Modular: Factory-Built Architecture is the Way Out of the Housing Crisis

Modular housing lacks the romantic, bespoke quality many people look for in architecture. Firms like Cutwork are changing these perceptions. The post The Future is Modular: Factory-Built Architecture is the Way Out of the Housing Crisis appeared first on Journal.

For more ways to supercharge your workflow, check out more articles in our Tech for Architects series, which includes our recommendations of Top Laptops for Architects and Designers.

In December 2023, Binyamin Appelbaum published a timely op-ed in the New York Times. The headline was a provocative question, “Why Do We Build Homes in the Same Way That We Did 125 Years Ago?” and the core claim was that it is no longer economically viable to build the majority of single-family homes on site.

Appelbaum writes that in 2022, “completing a house took an average of 8.3 months, a month longer than it took to build a house of the same size back in 1971.” He argues — and I agree — that this is simply far too slow during a period when America is in the midst of a housing crisis. Due in large part to the low housing supply, it now takes an income of over six figures to afford the average home in America. This pushes more and more families into the rental market, where they are often subject to the whims of private landlords who have been raising rates dramatically since the end of the pandemic. (the shortage of public housing is even more profound than in the private market).

Housing scarcity pressures all other aspects of society, leading to personal and political despair as millions of Americans conclude that the economy simply does not work for them. This is especially true for younger Americans. A similar picture can be seen in Canada, the UK, and other developed countries.

Modular housing sometimes gets a reputation for drabness due to midentury projects like this one. Mtaylor848, Prefabricated concrete houses on North Parkway, Seacroft, Leeds (9th November 2023), CC BY-SA 4.0

Appelbaum believes that solving this problem will involve factory-made or modular housing. In America, this has never really caught on, especially for free-standing single-family homes. Even in the early 1970s, when the federal government provided subsidies for modular home construction, only about 25,000 new homes ended up rolling off the assembly line. In 2022, only 2 percent of new single family homes were built in factories. The statistic is a little higher for multifamily apartment buildings, but still, modular construction has never been the norm in the US.

Part of the resistance to modular housing comes from the perception that this method, while faster than traditional construction, isn’t really a money saver. Shipping larger prefabricated sections of houses or apartment buildings is expensive, and often offsets the savings that come from reduced labor costs on site. However, due to new techniques in manufacturing, this is starting to change.

Applebaum profiled a start-up called Fading West, which operates a factory in the Colorado mountain town of Buena Vista. According to Fading West, a house from their factory can be completed in half the time as a traditional house for as little as 80 percent of the cost. This figure includes the time spent in construction in the factory. On site, they can assemble houses in a couple of hours after the foundation has been established.

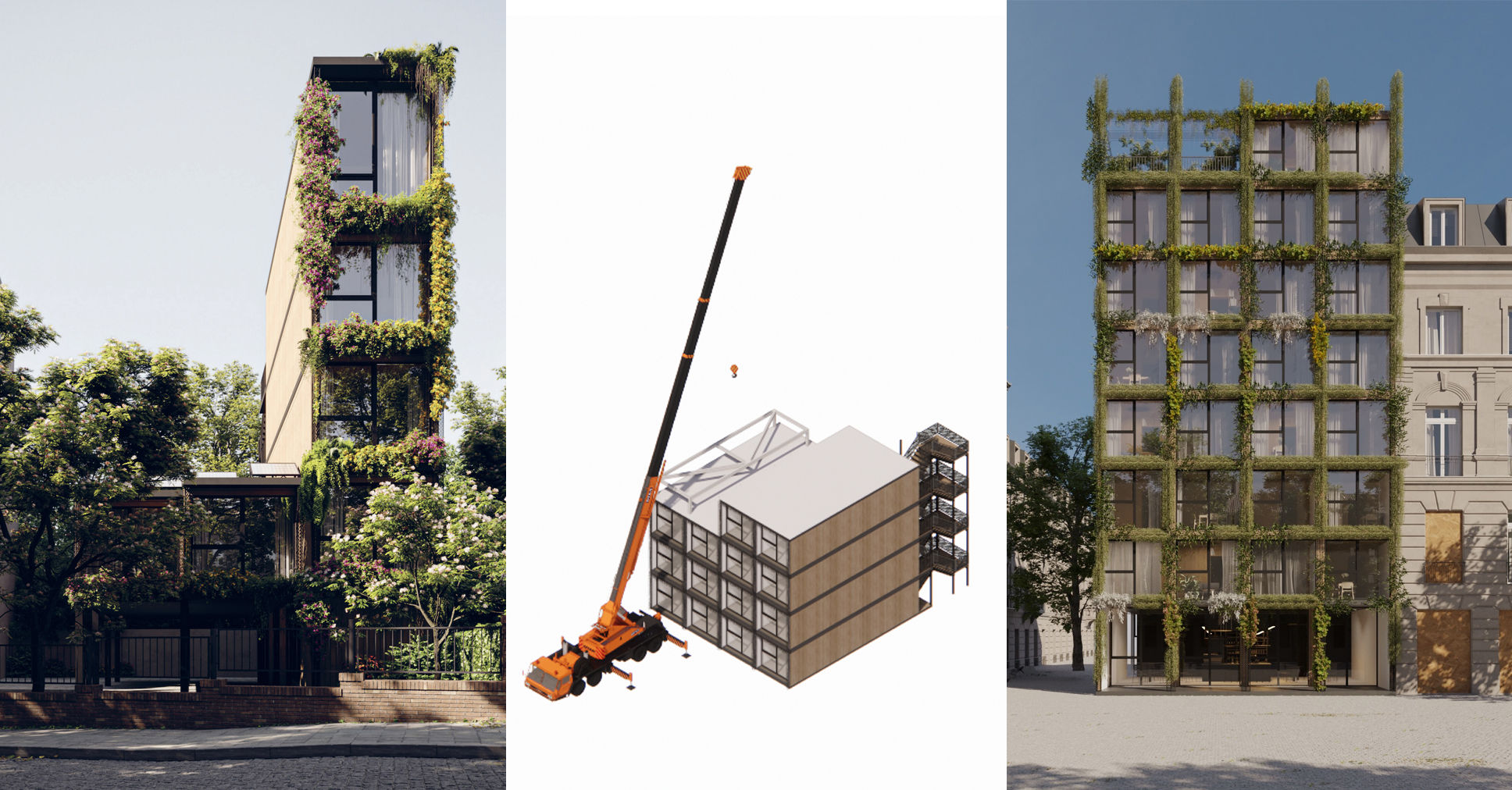

Rendering of apartment building being constructed with CutWork‘s ReHome modular system. Originally, this system was designed to help rebuild Ukrainian cities after the war, which is why the surrounding buildings are portrayed as boarded up and damaged.

The other big objection to modular housing is aesthetic. There is still a resistance to living in “cookie cutter” housing. And it is true that the single and multi family homes developed by Fading West have a generic, if clean look designed to blend into an American suburban context. When it comes to high density developments, the very term “modular apartment building” evokes heavy, weatherbeaten Brutalist structures built around midcentury. (I like this stuff, but the public disagrees, and pragmatically this approach to public housing by and large did not produce workable communities). For most people, modular housing lacks that Romantic, bespoke quality they look for in architecture.

The time has come, however, to let go of sentimentalism and fall in love with mass production. People need to be housed, and they need housing that they can realistically afford on their income. This is a political demand, but it is also a utopian vision. A society where beautiful, functional housing is within reach is one that enables human flourishing. As Le Corbusier said, “Space and Light and order. Those are things that men need just as much as they need bread or a place to sleep.” Modular housing is the best bet of providing this quickly, and with the right kind of ingenuity this method can be used to design neighborhoods that are walkable, beautiful, and in the best sense of the word, modern.

One firm that is leading the way in this area is the Paris based firm Cutwork. They have introduced ReHome, an “off-site modular construction solution that while originally conceived to address the housing crisis in war-torn Ukraine, seeks to address the global housing crisis equally in times of emergency and stability and the human right to shelter.” Essentially, ReHome consists of stackable concrete blocks with glazed façades that can be assembled into apartment buildings of various shapes.

ReHome‘s basic units, the modular blocks, can be fitted to create different apartment layouts.

“Composed of 27 square meter modular units, the blocks can be stacked like LEGO bricks to complete a full residential block up to six stories in significantly less time and cost compared with traditional construction methods (up to 40% less time for teams on-site to complete the building),” explains the firm. “This modular nature allows ReHome to adapt to a wide-range of conditions and contexts, enabling rapid re-urbanization across diverse environments.”

In its simplicity and flexibility, the scheme evokes Metabolist architecture, the midcentury Japanese movement that never took off but still captures the imagination of design enthusiasts. Like the ReHome system, Metabolism was rooted in the idea that simple elements can be combined in unique ways to create structures that are easily modifiable.

The most striking aspect of these towers is their light, minimalist appearance, which is far more pleasing to my eyes than most of the large apartment complexes currently being built near me in Bergen County, New Jersey. Trellises on the façade allow for greenery to grow, adding liveliness and variety to structures that themselves are quite spare. The flexibility of this system means that it can be used to create very different neighborhoods, with completely unique layouts and their own visual identities. Unlike the midcentury modular apartment blocks that people love to hate, ReHome neighborhoods do not come across, visually, as heavy and monotonous. They are light, luminous, variegated and homey.

Cutwork is very intentional in making sure their designs are not weighed down by 20th century nostalgia. “Cutwork was founded in the belief that the cities we live in were built for a world that no longer corresponds to the one we live in today,” they write. “If the challenge of the last century was to densify cities vertically, the challenge of today is to rethink our spaces to make them more elastic in their usages and in ReHome, Cutwork demonstrates their continued commitment to this.”

The 21st century can be one of growth and change only if governments and developers work together to meet the housing needs of the population. Projects like ReHome show that this can lead to future cities that are not only more equitable, but more beautiful as well.

For more ways to supercharge your workflow, check out more articles in our Tech for Architects series, which includes our recommendations of Top Laptops for Architects and Designers.

The post The Future is Modular: Factory-Built Architecture is the Way Out of the Housing Crisis appeared first on Journal.

What's Your Reaction?