Recycled aluminium "is a material we'll be using for the next 100 years" says Lars Beller Fjetland

An aluminium alloy made from 100 per cent recycled waste will be a game-changer for the furniture industry, according to Norwegian designer Lars Beller Fjetland. Beller Fjetland was the artistic director for 100R, a Milan design week exhibition staged by industrial manufacturer Hydro featuring extruded aluminium objects created by seven different designers. The exhibition marked The post Recycled aluminium "is a material we'll be using for the next 100 years" says Lars Beller Fjetland appeared first on Dezeen.

An aluminium alloy made from 100 per cent recycled waste will be a game-changer for the furniture industry, according to Norwegian designer Lars Beller Fjetland.

Beller Fjetland was the artistic director for 100R, a Milan design week exhibition staged by industrial manufacturer Hydro featuring extruded aluminium objects created by seven different designers.

The exhibition marked the launch of Hydro Circal 100R, a newly developed alloy billed as "the world's first industrial-scale aluminium product made entirely of post-consumer scrap".

Speaking to Dezeen at the exhibition, Beller Fjetland said this type of aluminium could play a pivotal role in the transition towards a zero-carbon, circular future.

"As a designer, you constantly ask yourself: Am I part of the problem or part of the solution? With this project, we are definitely part of the solution," said the designer.

"This is a material we'll be using for the next 100 years at least," he told Dezeen.

Hydro Circal 100R is the first product of its type on the market.

It was highly challenging to develop, due to the difficulty in removing paint, plastics and other contaminants from post-consumer aluminium, but could offer huge benefits for decarbonisation, according to the brand.

With a reported 0.5 kilograms of CO2 produced for every kilogram of aluminium, Hydro claims the carbon footprint of this material is 97 per cent lower than the global average for aluminium.

It also boasts the same benefits as other aluminium alloys; it is lightweight, easy to shape, resistant to corrosion and can be infinitely recycled without degrading in quality.

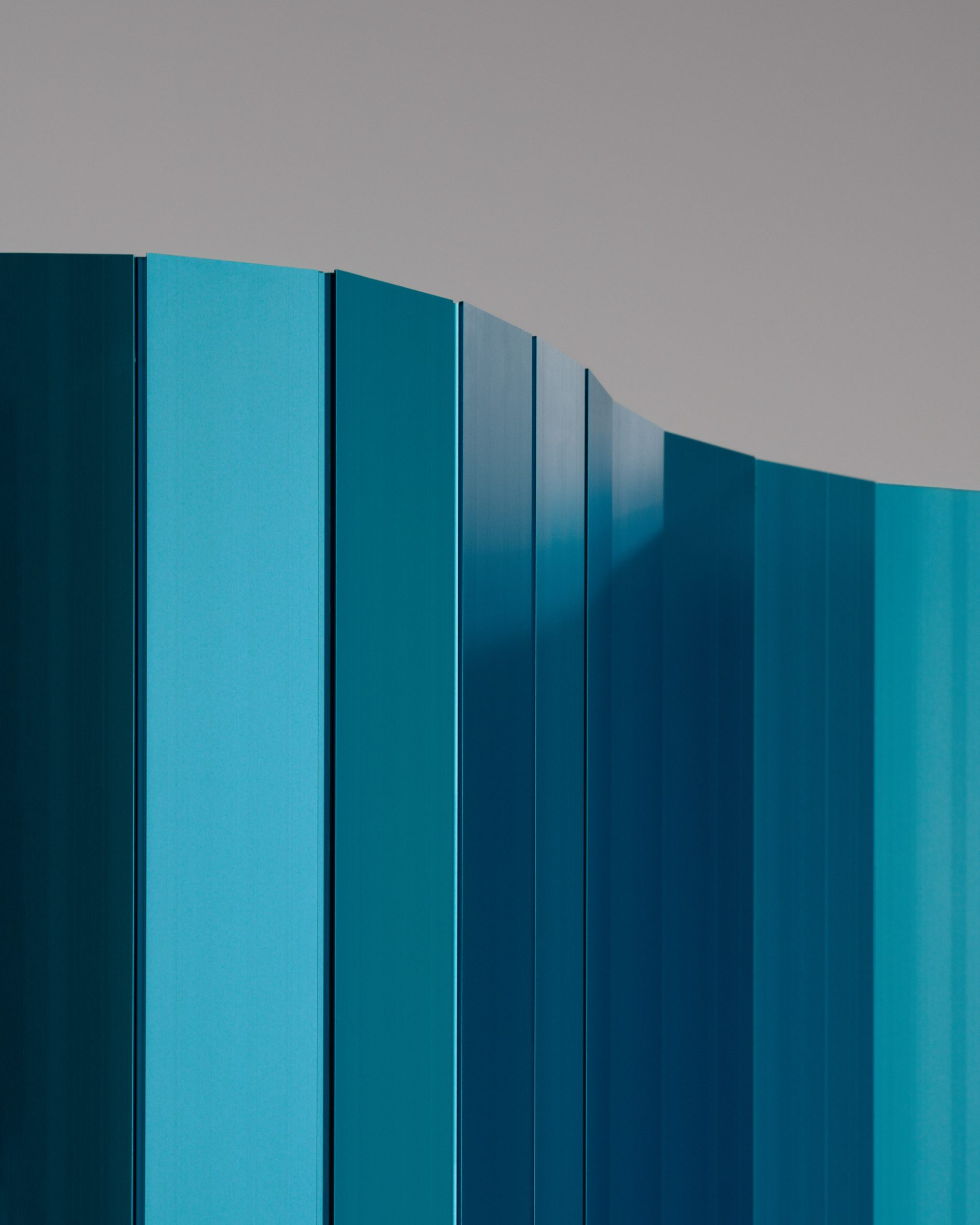

An anodising process makes it possible to apply a colour finish to the metal without affecting the material's recyclability.

The 100R exhibition represents an ambition for Hydro to expand outside its core business – primarily in sectors such as aviation and construction – by branching into the design industry.

"I'm convinced that there is a huge market for extruded aluminium in this sector," Beller Fjetland said.

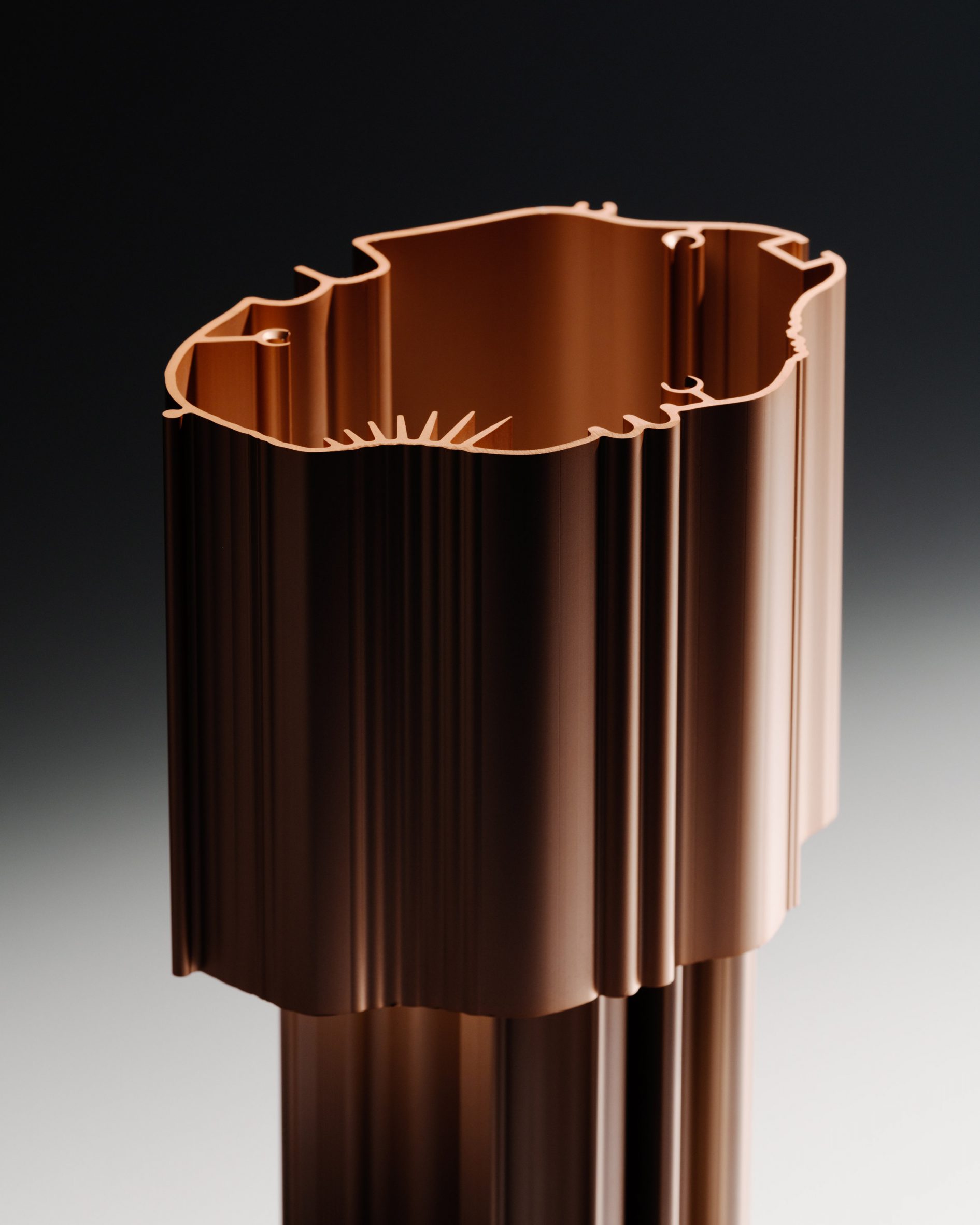

Extruded aluminium is made in a process that involves pressing a heated aluminium billet through a die, resulting in long, continuous lengths with a specific cross-sectional profile.

The process of cooling determines the strength and quality of the material.

The seven designers participating in 100R were tasked with designing furniture and homeware objects that could be produced using nothing but extruded aluminium.

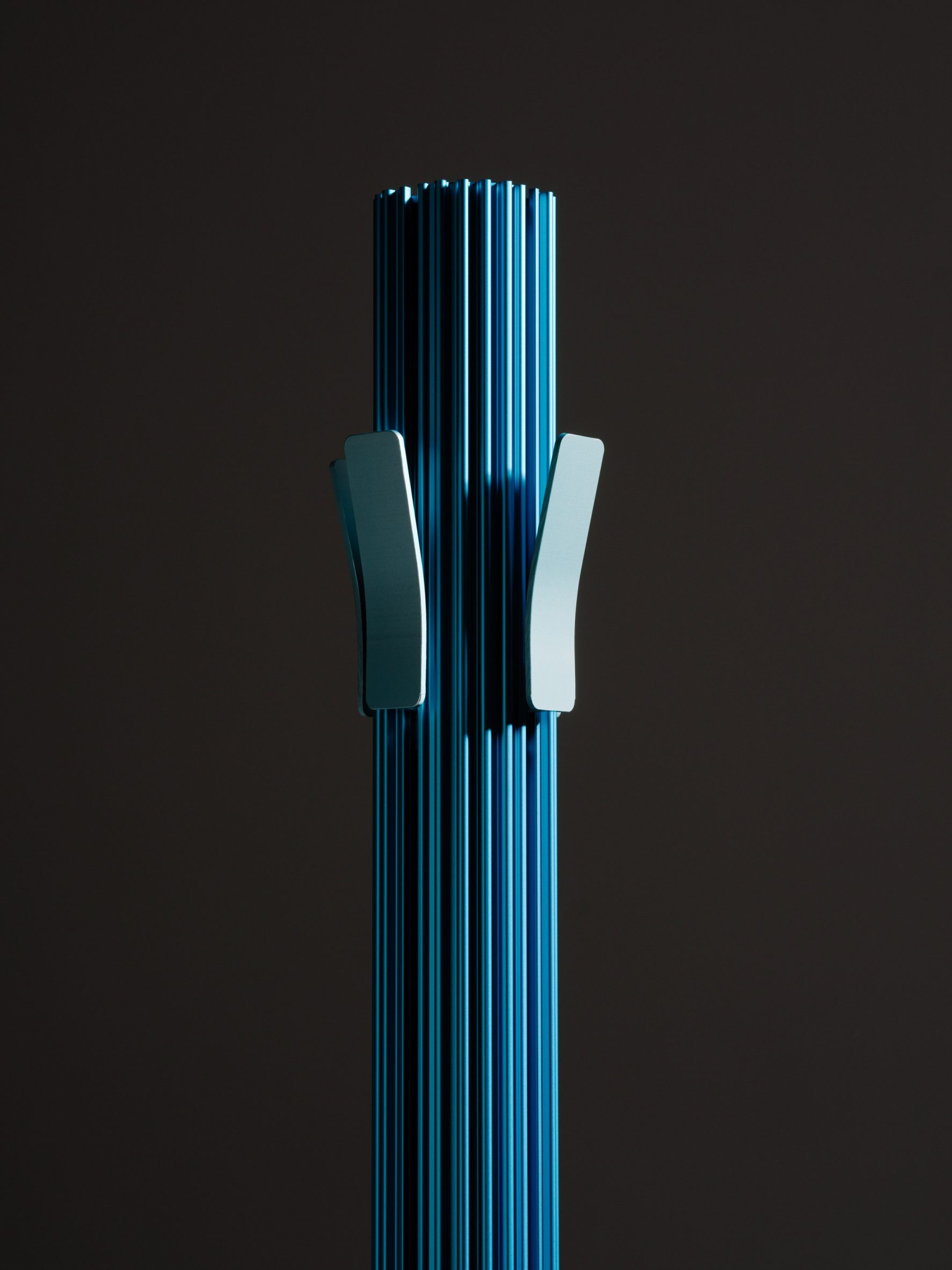

The brief called for mono-material designs with no additional fixings – components simply slot together, with joints integrated into the extruded aluminium profiles.

Among the most ambitious examples are designer John Tree's Billet Chair, which was cleverly produced from a 200-millimetre press, and Paris-based Inga Sempé's Grotte table lamp, which sees two highly intricate profiles slot together perfectly.

French designer Philippe Malouin devised a modular shelving system that can be produced in lengths of up to six metres, while Earnest Studio founder Rachel Griffin developed a flexible partition screen made of interlocking elements.

A table lamp by British designer Max Lamb, a coat stand by Norwegian designer Andreas Engesvik and vases by US-based Shane Schneck complete the collection.

"This project is challenging perceptions about what extruded aluminium is, what it can do and what it can be," said Beller Fjetland.

None of the designs are yet being produced commercially, but Beller Fjetland believes it's only a matter of time.

"These could all be commercial products," he said. "Even an intricate design like Max's can be simple to produce; the cost is almost entirely determined by the weight and the amount of material you use."

Beller Fjetland has been collaborating with Hydro for some time. At the previous Milan design week, they jointly exhibited a bench made from 90 per cent recycled aluminium.

He believes this material will increasingly attract the interest of other designers and furniture manufacturers.

"This is a place where dreams can come true," he said. "It's mouthwatering for a designer; you can do just about anything."

In the context of Milan design week, where many brands claim to be producing sustainable products, the designer believes this project offers an alternative to the concept of "new for new's sake".

"If a design is future-ready, because it's easier to dismantle, or because it can be produced using less carbon and less water, then new is good," he concluded.

Dezeen produced a video about the 100R exhibition, which was published earlier this month.

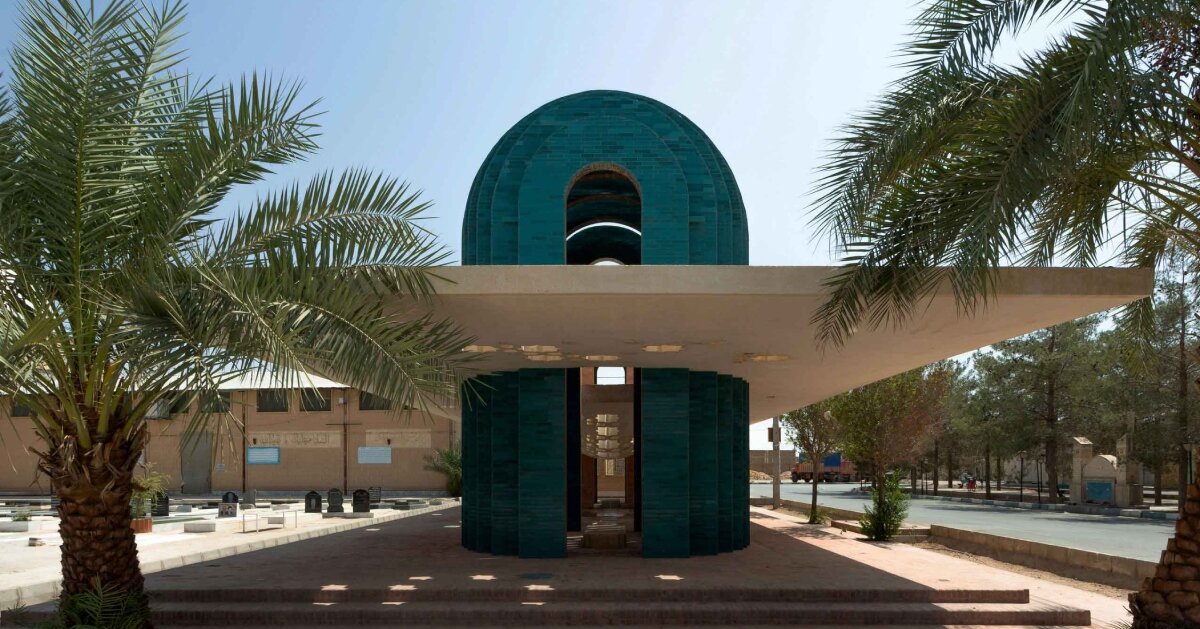

It shows the objects displayed in a scenography formed of blocks of recycled aluminium sourced from a pipe factory, revealing the material in its raw state.

"They really tell people the story about this material," added Beller Fjetland.

Milan design week took place from 15 to 21 April 2024. See Dezeen Events Guide for an up-to-date list of architecture and design events taking place around the world.

The post Recycled aluminium "is a material we'll be using for the next 100 years" says Lars Beller Fjetland appeared first on Dezeen.

What's Your Reaction?